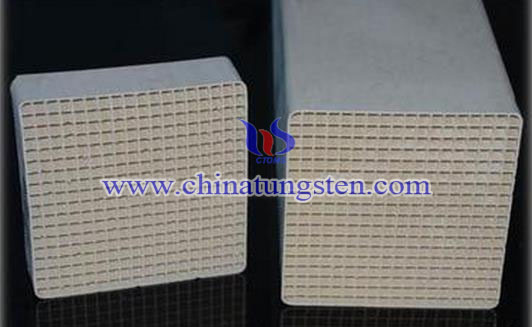

Glass Furnaces Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 31 March 2016 16:26

V-W-Ti based SCR denitration catalyst is the most effective denitration catalyst for glass furnace boiler industry; there is a high content of Na2O in the glass furnace exhaust, which is easy to cause catalyst poisoning. For solving this problem, tungsten trioxide is added to SCR denitration catalyst for improving the catalysts’ anti-vulcanization, anti-poisoning ability; the shape of the substrate is improved to enhance the denitration efficiency.

The boiler includes pot and furnace, which is an energy conversion device by outputting heated steam, hot water or organic. The boiler causing steam is called steam boiler, often short for boiler, used for thermal power stations, ships, locomotives and mining enterprises. The main principle of the boiler is using thermal energy released after fuel combustion or industrial production of heat transfer to the water in the container, so that the water reaches a certain temperature or steam pressure. About the part of combust equipment, the fuel constantly burned and releasing heat, the generated high temperature flue gas spreads by heat and delivers to the boiler heating surface, so the temperature itself gradually lowered, and finally discharged from the chimney. Therefore, the emissions of the boiler chimney also have great polluting.

The tungsten trioxide SCR denitration catalyst particularly suitable for glass furnaces has the following properties:

1. Components: ultrafine crystal form of anatase type titanium dioxide as the base material; tungsten trioxide and vanadium pentoxide as the main active ingredients; and some other components;

2. Properties: high resistance to alkaline poisoning, especially strong in anti-Na2O poisoning; high activity, thus to reduce the amount of volume; can be applied in natural gas, coal gas and coal-fired, etc;

3. The main technical parameters: temperature window of 280-420℃; life within the range of 16000-24000 hours; the ratio of sulfur dioxide and sulfur trioxide is below 0.8%.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com