Tungsten Scraps Recycle APT--Acid Leaching Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 March 2016 18:03

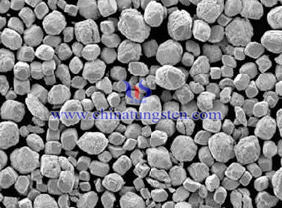

Ammonium paratungstate (APT) being the important intermediate product of tungsten ore translating into tungsten products, its demand is growing in high-speed with the world economy development rapidly. Tungsten scraps are increasing at the same time. We present a method that directly translating tungsten oxide into ammonium tungstate by acid leaching method, and then carrying out crystallization to recycle APT. The steps are as follows:

Ammonium paratungstate (APT) being the important intermediate product of tungsten ore translating into tungsten products, its demand is growing in high-speed with the world economy development rapidly. Tungsten scraps are increasing at the same time. We present a method that directly translating tungsten oxide into ammonium tungstate by acid leaching method, and then carrying out crystallization to recycle APT. The steps are as follows:

1. Acid leaching and removing impurity: put the tungsten scraps into acid, reacting in the conditions that: acidity of 50-120g/mL, temperature of 60-100°C;

2. Drying and oxidizing: carrying out solid-liquid separation after the slurry acid leached and impurity removal, and then transferring into he drying furnace for drying after washing and purging, and transferring into the furnace for oxidation treatment at 600-1000°C after complete drying, now tungsten is oxidized into tungsten oxide;

3. Transformation: place tungsten oxide into ammonia solution, adding oxalic acid with the temperature heated and controlled at 80~150°C; set the transition pressure among 0.3~1.0MPa, keep stirring for 5-9 hours to give the crude acid ammonia solution, meanwhile trace the impurity elements Co, Ni, Fe, Ca ions into hydroxides and precipitation to separate;

4. Purification: determination the content of metal ion impurities Cu, Al, Mg and Ti, then adding ammonium sulfide, hydrogen peroxide for precipitation, separating to obtain pure ammonia tungstate solution;

5. Evaporation, crystallization and drying to obtain ammonium paratungstate products.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com