Warm Compacting Process Impact on Tungsten Copper Density (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 18:08

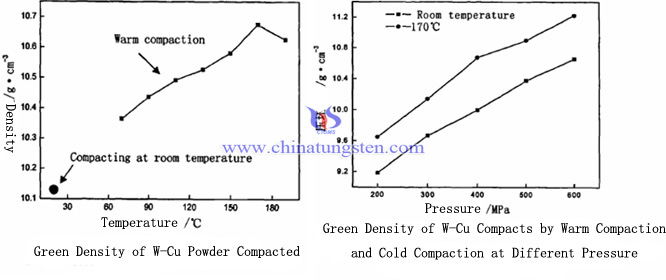

Warm compacting process is a kind of new technology based on conventional molding process. Compared with conventional powder metallurgy (PM), warm compacting process require add special binder in the powder before compression and heating of moderate temperature lower than the conventional powder metallurgy desired temperature, then use conventional methods to obtain high-density powder compact was pressed. At present, warm compacting process can be widely used in some iron-based powder metallurgy parts fabricating, which can remarkably improve the density and properties of tungsten copper sintered body. We will discuss the process temperature and pressure applied on tungsten-copper material to analyze the impact of temperature and pressure from the temperature and pressure of pressing both temperature and pressure process of tungsten copper compacted density.

Temperature controlling plays an importance role in warm compacting process, in order to achieve the optimum temperature, related scholars at the same pressure do the compacting experiments at different temperatures. Experiment uses tungsten copper mixed powder (add 0.8% binder) at a pressure of 400MPa, at different temperatures for tungsten copper compacts pressed. Combined figure below we can see that the green density warm compaction under high pressure in cold forming the blank (at room temperature) as compared to the density. This is due to the cold pressing the powder in a binder lubricating can not work effectively, so the green density produced little effect; The temperature and pressure conditions in the binder may well play a role in improving the friction between the powder and the powder and die wall, thereby increasing the density of tungsten and copper compacts.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com