Seismic Tungsten Wire Production Processes

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 February 2016 18:57

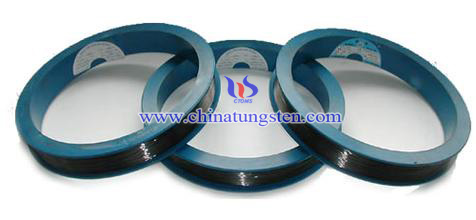

Seismic tungsten wire was produced by doping K, Si, Al and other elements. It is widely used in the lighting system at vibration environments. Seismic tungsten wires were divided into three types. First kind is seismic tungsten wire doping with Si, Al and K elements and this type has good organizational structure and high-temperature sag resistance value is small. Second kind is seismic tungsten wire doping small amount of Fe or Co elements whcih based on Si, Al, and K elements doped, and this seismic tungsten wire has better high temperature resistant, sag resistance and other performance; third kind is tungsten rhenium alloy wire which produces by doping Si, Al, and K elements and small amount of Re into tungsten powder. Tungsten rhenium alloy wire has good organizational structure, high recrystallization temperature, resistivity, elongation and other good properties.

Seismic tungsten wire production processes are as following:

1. Mix the raw material and the doping elements evenly by proportionately, and dried. Then placed them in a hydrogen furnace occurs reduction reaction by sintering. The raw material can be used are ammonium paratungstate (APT), ammonium metatungstate (AMT) and tungsten blue (TBO), but the study showed, blue tungsten oxide has high chemical resistance, good doping effects, large specific surface area and excellent fast rate, and other good performances, so it can produce seismic tungsten wire with better performances.

2. The reduction calcined powder after wash by acid and then drying, pressing, sintered.

3. The sintered blank after thermal processing obtains seismic tungsten filament.

In the preparation process, there are basically three methods for Si, Al, K, and other elements doping. One is mixing tungsten powder and doped powder, namely solid - solid doping. Although this method has simple process, but it is difficult to make doped powder evenly distributed in tungsten powder and will bring some problem on the subsequent processing; the second is the matrix solution and the doping solution, namely liquid - liquid doping. This doping method has complex processes which are not suitable for industrial production; third doping method is powder and doping elements mashing solution doping that solid - liquid doping, it not only has simple process steps, produced seismic tungsten wire has a good performance which widely used in the industry.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com