Effect of Tungsten Powder Granularity on Tungsten Copper Density

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:00

The granularity of tungsten powder plays an important role in the comprehensive properties, such as the hardness, the density, the electrical conductivity and micro-structure and so on. Here we are concentrated on the effect of tungsten powder granularity on the density of tungsten copper electrode.

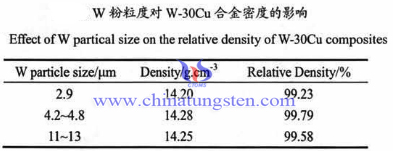

Take W-30Cu tungsten copper electrode as an example, there is sheet of effect of the granularity of W particle on the relative density of W-30Cu tungsten copper electrode (different size, includes 2.9μm, 4.2-4.8μm and 11-13μm) as follow:

Theoretically, the granularity of tungsten powder is one of the main factors of the effect of tungsten copper electrode structure and properties. Viewed from the sheet, we can see that the experiment were used Fibonacci particle size of 2.9μm, 4.2-4.8μm and 11-13μm tungsten powder by pressing, infiltration and other technology to prepare W-30Cu tungsten copper electrodes. Several tungsten powder (W) sizes of the resulting tungsten copper alloy electrical extreme density in 14g / cm3 or more, relative density has reached more than 99%, when the tungsten powder particle size 4.2-4.8μm, the relative density of up to about 99.79%, and when the tungsten powder particle size is small about 2.9μm, relative density or lower density, relative density of about 99.13%.

Generally, the smaller granularity of tungsten powder, the smaller capillary radius and the higher liquid metal increases, it is more beneficial for the infiltration processing. However, finer tungsten powder has larger specific area and higher energy of surface, which internal close bores of the porous tungsten skeleton will increase and the liquid metal (copper, Cu) is difficult to penetrate. In addition, the finer the particle size of the tungsten powder, tungsten copper alloy tungsten particle size is smaller, the possibility of greater obturator and defects, tungsten copper electrode so that the uniformity of the overall organization is also affected. Therefore, selecting a moderate size tungsten powder is more suitable for tungsten copper alloy electrode production and processing.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com