Lanthanum Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 17:17

Currently, the tungsten electrode, rare earth tungsten electrode and the composite electrodes are widely used in chemical, electrical, mechanical, construction, aerospace and other fields. But with the development of scientific and technological, tungsten inert gas welding and plasma welding field, there are higher requirements of electrode material and performance have been put forward . The properties of lanthanum tungsten electrodes are superior to thorium tungsten electrode and cerium tungsten electrode which is one of the most widely used electrodes.

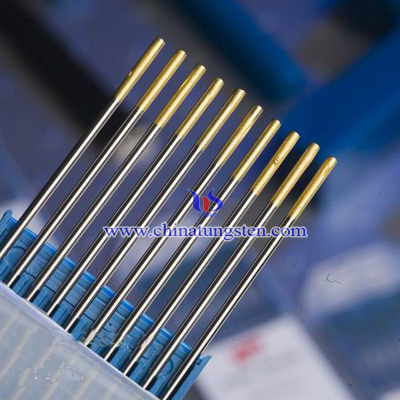

Lanthanum tungsten electrodes have good mechanical cutting performance, creep resistance, ductility and high recrystallization temperature is currently the most popular electrode. It was developed from the European country in the 1980’s to replace thorium tungsten electrode. The tip colors of lanthanum tungsten electrodes are varies which depend on the amount of lanthanum oxide (La2O3) doping. When La2O3 doping amount is 0.80 to 1.20%, the tip color is black; when La2O3 doping amount is 1.30 to 1.70%, the tip color is golden yellow; when La2O3 doping amount is 1.80 to 2.20%, the tip color is sky blue.

Lanthanum tungsten electrode is mainly used in DC welding and AC welding. The experiment found that the 1.5% lanthanum oxide content in lanthanum tungsten electrode has similar conductive properties with thorium tungsten electrode which has 2% thorium oxide content. Besides, the burn rate of lanthanum tungsten electrode is smaller and has longer service life. On the other hand, lanthanum tungsten electrode is a non-polluting, non-radioactive green electrode. So it concern in European countries and Japan is very high.

Lanthanum tungsten electrode production method:

1. Add the appropriate amount of La2O3 powder into tungsten trioxide powder, after twice reduction to give W-La2O3 powder. The first reduction temperature is at 600 ~ 700 ℃and time is about 2 to 3 hours; the second reduction temperature is controlled at 800 ~ 970 ℃ and the hydrogen flow is 0.5-2.0m3 / h.

2. After pressing, swaging, stretching, straightening, polishing and other processes obtains the desired electrode rod.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com