Tungsten Polymers: The Best Replacement To Lead

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 15:17

Lead is a heavy metal and can be poisoning the day to day operations of human organs are inhibited. Despite these health risks, lead is very useful in industries today because of the properties it possesses, such as its malleability and low melting point making it easy to mold and melt, in addition to its low cost which makes it economical for use for industrial purposes.

Recent studies show that the heavy usage and poor disposal of lead products for decades has caused irreversible effects to the environment and as such lead is now ranked as the second most hazardous substance by the United States government. A kind of material without toxic needed badly, tungsten polymers are being introduced as an effective lead alternative in a variety of applications for which lead has traditionally been used. This push for alternatives is due to the threat that leads poses to the environment and to human health.

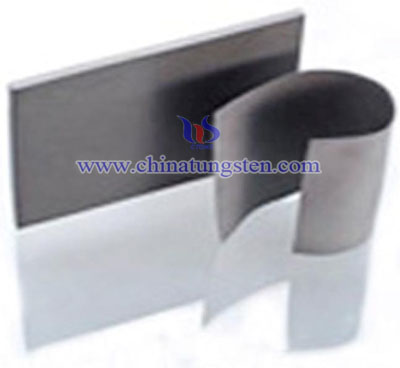

Therefore, tungsten polymers have become a notable alternative to lead in numerous applications because they can match the physical properties of lead, like high density, while being environmentally benign. This polymer composite is made up of tungsten powder and a plastic base resin, which are compounded together into a thermoplastic material at 11 g/cc, the same density as lead. The base resin systems are made up of; polysulfones (PSU), co-polymides, polyamides (PA), polymethylpentenes (PMP), polyurethanes (TPU), acryloynitrile butadiene styrene (ABS), polyethylenes (PE) and polyetheretherketones (PEEK).

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com