Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅴ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:50

In last part we know that the tungsten carbide tools PVD-coated with (Ti,Al)N and (Al,Cr)N coating films are tested in cutting hardened sintered steel to compare the effect, since (Al,Cr)N coating film is a new film. In this part we will get result and make analysis.

Results and Discussion

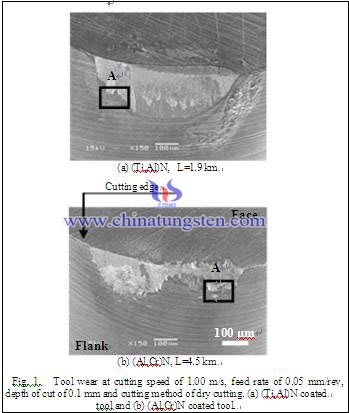

The hardened sintered steel was turned with two kinds of coated cemented tungsten carbide tool at a feed rate of 0.05 mm/rev and a depth of cut of 0.1 mm. Fig.1 shows the SEM observation of the tool wear. Fig.1 (a) and (b) show the case of the (Ti,Al)N coated and the (Al,Cr)N coated tool at a cutting speed of 1.00 m/s, respectively. In the case of the (Ti,Al)N coated tool shown in Fig. 1 (a), a crater is found on the rake face along the cutting edge, and adhesion on both the rake and flank faces is not remarkable either. Also, the flaking of the coating layer is not remarkable. In the case of the (Al,Cr)N coated tool shown in Fig. 1 (b), there is no remarkable crater on the rake face. And adhesion on the flank face is found, while the flaking of the coating layer is also unremarkable.

(To be continued. This article is divided into several parts. Here is part 5. For part 4, please refer to http://news.chinatungsten.com/en/tungsten-information/80616-ti-10433)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com