Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅳ

- Details

- Category: Tungsten Information

- Published on Friday, 20 November 2015 16:47

In last part we know that the study is to explore the effectiveness and wear mechanism of tungsten carbide tool with (Al,Cr)N coating film coated by PVD technology in turning hardened sintered steel.This part goes on explaining how the experiments go.

2. Experiment Details

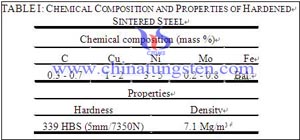

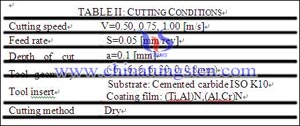

The work material used was hardened sintered steel from diffusion alloyed powder. This material had a density of 7.1 Mg/m3, and many pores were observed when examining the structure by microscope. The chemical composition and the mechanical properties of the hardened sintered steel are shown in Table I. That is, the hardened sintered steel had a hardness of 339 HBS. The cutting conditions are shown in Table II. The tool material of the substrate was cemented carbide, and two types of PVD-coated cemented tungsten carbide tool were used. Namely, the coating films used were (Ti,Al)N and (Al,Cr)N coating film. (Al,Cr)N is a new type of coating film. The configurations of tungsten carbide tool inserts were TNGA160408. The insert was attached on the tool holder MTGNR2525M16. In this case, the tool geometry was (-6, -6, 6, 6, 30, 0, 0.8 mm). The turning tests were carried out on a precision lathe (Type ST5) with an added variable-speed drive. The driving power of this lathe is 7.5/11kW and the maximum rotational speed is 2500 min-1. The tool wear of the two kinds of turning insert was investigated.

(To be continued. This article is divided into several parts. Here is part 4. For part 3, please refer to http://news.chinatungsten.com/en/tungsten-information/80615-ti-10432; for part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/80617-ti-10434)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com