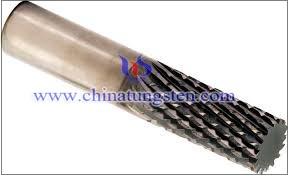

Introduction to Tungsten Carbide Tipped ReamersⅠ

- Details

- Category: Tungsten Information

- Published on Thursday, 17 September 2015 17:05

(This article is divided into two parts and this is partⅠ. For Part Ⅱ please refer to

General View

Tungsten carbide tipped reamers are basically the same in design as high-speed-steel reamers, with the exception that the cutting blades have carbide tips. They may be used on a wide range of materials, including all the common industrial metals and the machinable plastics. The extreme hardness of cemented carbides enables them to withstand wear and abrasion; however, these materials are relatively brittle, and the reamer body, the flutes or blades, and the carbide tips themselves must definitely be shaped and dimensioned to resist deflection. Nearly all carbide-tipped reamers are intended for machine reaming.The terminology and definitions for reamers adopted and published by the ANSI are generally applicable to carbide-tipped reamers.

Mechanism and Parameters

Certain angles and clearances are embodied in the cutting elements of carbide-tipped reamers to obtain cutting action in the proper places, prevent friction, and clear the chips. Practically all the cutting is done on the chamfer, which is in the form of a truncated cone on the entering end of the reamer. This chamfer is shaped to start the reamer properly in the hole.

A clearance on the chamfer of 6 to 8 degrees on the carbide tip and a secondary clearance of 10 to 15 degrees on the steel body have proved to be satisfactory for most work piece materials. Under good work conditions and proper alignment of the reamer and the work, a back taper of 0.003 in/in of flute length is adequate. Back taper should be increased to prevent binding of only slightly dull tools when reaming very abrasive materials. In general, circular land widths may range from 0.007 inches on ¼ inch-diameter to 0.020 inches on 1 ½ inch-diameter reamers. Primary relief angles on the carbide tip range from 15 degrees on a ¼ inch-diameter to 7 degrees on a 1 ½ inch-diameter reamers

Solid carbide reamers are available in diameters from 1/16 to 3/8 inches, and larger on special order. Since sintered carbide is a rigid material, a solid carbide reamer will finish a hole within close tolerances. If a hole is drilled slightly out of round or out of parallel, a solid carbide reamer will usually not follow the irregularities but will finish a true hole around its own axis. Rough and finish-reaming operations often can be combined into one through the use of solid carbide reamers.

-to be continued-

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com