Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅴ

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 16:39

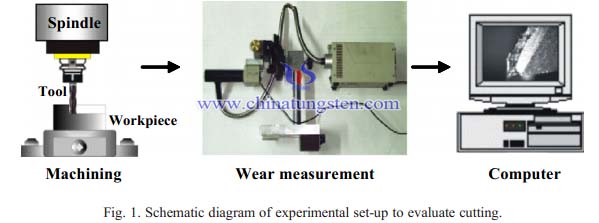

2.3 Cutting test

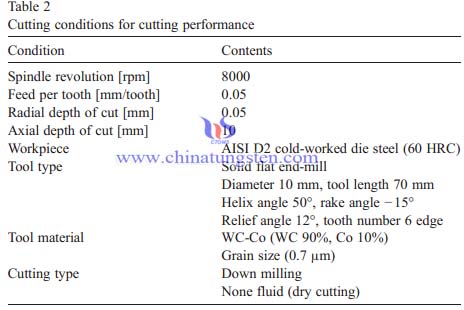

Fig. 1 shows the schematic diagram of the experimental set-up to evaluate cutting performance . The experiments were carried out without any coolant in a vertical machining center (MAKINO, V-55). Tool wear was measured by a CCD camera (PULNIX , X200 ), which was attached on the machine table. The cutting test was started with a fresh cutting tool, and the machining process was stopped at certain intervals of cutting length in order to measure the width of flank wear. Flank wear was obtained by the average value measured on three points of cutting edge within the axial cutting depth. The flank wear of 0.3 mm was used as a tool life criterion for a comparative evaluation of the TiN coating on the WC-Co substrate and the three types of the TiN coating tools with Co interlayer. The workpiece used in the experiment s was die steel (AIS I D2, 60 HRC). The experiments were carried out under cutting condition shown in Table 2 . The tool manufacture used at experimentation was made by Sung-Jin Tech Co. (Korea) as solid flat end-mill. To verify the goodness of fit for tool wear distribution, the best coated cutting tool was tested 18 times repeatedly. The probabilistic function of tool wear was analyzed by normal, log-norma l and Weibull distribution. The χ2 (chi- square d) test was also used to verify the goodness of fit. This test allows us to compare a collection of categorical data with some theoretical expected distributions

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com