TiN/TiC Coated Tungsten Carbide Inserts Flank Wear

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:36

Flank wear is referred to the wear eroded by the portion of the tool in contact with the finished workpiece, which is an important factor to examine the life of coated tool.

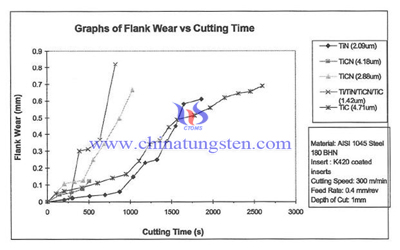

In the research , if the TiC coated tungsten carbide inserts’ coating thickness is 4.71um while the TiN coating ones having a thickness of 2.09um are put into the turning operations, it could be observed that the flank wear growth in inserts having TiN coating appears to be much faster till the tool failure.

Besides the thickness issue which maybe likely to cause the rapid wear growth of TiN coated inserts, the other factors such as temperature and heat are identified to have a possibility to be attributed to faster failure of tool life. Since turning operations typically involve with high interface temperature and a large amount of heat and high speed, which may cause reduction of coating hardness and hence resultant of low wear resistance. In addition, the large heat would soft the substrate and cause cutting edge thermal deformation, which also adds to the failure of coated tungsten carbide inserts.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com