TiN/TiC Coated Tungsten Carbide Inserts Crater Wear

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2015 15:35

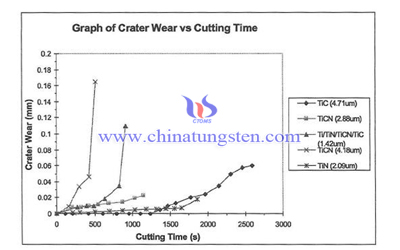

Crater wear is the wear caused by cutting chips contact with cutting tool erodes the rake face.It is known that the crater wear is normal for tool wear, and until it become serious enough to cause a cutting edge failure, it does not largely affect the use of a tool. And for which, the crater wear could be a factor to examine tool life.

In the turning operation test, when the TiC coated tungsten carbide inserts’ coating thickness is 4.71um while the TiN coating ones having a thickness of 2.09um, as the growth of the crater wear, the tungsten carbide inserts with TiC coating appears to have a relatively longer tool life before tool collapses. In addition, it could be examined that until 1250 seconds there is scarcely any growth of carter wear in TiC coated tungsten carbide insert, and after that a slow growth of this wear till tool failure. Interestingly, a similar growth of carter wear in tools having TiN coating is identified, although it has a relatively low tool life .

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com