Notes on Good Riveting -- Preparation

- Details

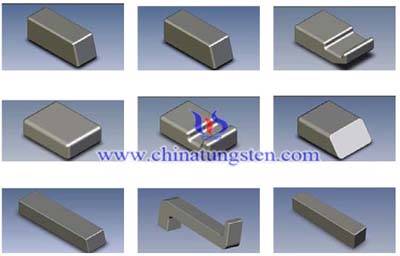

- Category: Tungsten Information

- Published on Thursday, 27 November 2014 08:57

Preparation:

Materials deburred on edges;

Holes laid out in correct locations, taking into account pitch and edge distance requirements

Holes centre-punched using a backing plate to avoid sheet distortion;

Parts assembled securely together and supported while being drilled with a sharpened bit of the correct size. Holes drilled squarely tosurrounding surface.

Parts disassembled and holes deburred;

Holes dimpled or countersunk if accepting AN 426 Flush head rivets.

Parts reassembled and clecoed;

Selection of new AN rivets of correct diameter and length;

Assembly well secured in a vice, a jig or on a workboard.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com