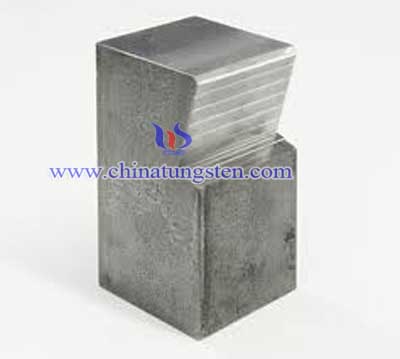

Precision Bucking Bar Devices

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 October 2013 08:55

Previous attempts have been made to develop a precision bucking bar which will produce a consistent butt regardless of operator skill. Such bucking devices suffer from a number of limitations. For example, they have universally required a relative large space behind the rivet, a luxury not available in many installations; they have not been available in a variety of geometries to avoid nearby obstacles; and they have not been of a conventional shape or size and thus have not felt familiar to an experienced operator. Hence, prior art precision bucking bars have not been well received in the field.

A second method for spreading a rivet employs an apparatus commonly known as “squeezes.” Squeezes typically include a pair of removable anvils, or points, a first point shaped to receive a rivet head, and a second provides a flat surface to interface the flat end of a rivet shank. To spread a rivet with a pair of squeezes, the rivet must be close enough to the edge of the workpiece for the squeezes to reach the rivet. The rivet is placed in a hole through multiple layers of sheet metal to be joined, the anvils are placed against each end of the rivet, and the operator squeezes the handle together to produce a compressive force between the head of the rivet and the end of the shank, thereby causing the rivet to spread. Automatic squeezes are also available wherein the points are pressed towards each other by a pneumatic or hydraulic actuator. As with driving a rivet, producing a quality butt requires the operator to maintain a consistently square angle between the face of the flat anvil and the rivet shank. Producing a consistent, quality butt requires an experienced operator.

Common to either type of spreading operation, a properly shaped butt of consistent thickness is essential to achieving maximum strength of the riveted joint. An improperly shaped butt may be too weak to hold under expected stresses or may concentrate stress in a small area resulting in failure of the workpiece.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com