Differences Between Thorium-Tungsten and Cerium-Tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 September 2025 14:27

Although both thorium-tungsten and cerium-tungsten electrodes are primarily made from metal tungsten and cerium-tungsten can often substitute for thorium-tungsten, differences in their dopants lead to variations in appearance, performance, production processes, and applications.

1. Definition

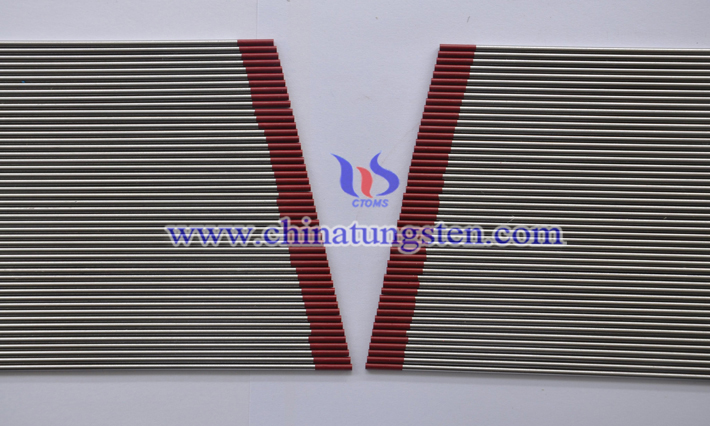

Thorium-tungsten refers to an electrode product with a chemical composition mainly consisting of tungsten and thorium oxide, designated as WT20, marked with a red color code. Its diameter ranges from 1.0 to 12.0 mm, with lengths of 150 mm or 175 mm.

Cerium-tungsten is an electrode product made by adding cerium oxide to a tungsten base through powder metallurgy and rolling, grinding, and polishing processes. It is designated as WC20, marked with a gray color code, with a cerium oxide content of 1.8%-2.2%. Its diameter ranges from 0.5 to 12.0 mm, with lengths of 150 mm or 175 mm.

2. Performance

Both electrodes exhibit low electron work function, low burn-off rate, strong current-carrying capacity, easy arc initiation, stable arc beam, long service life, good electrical conductivity, mechanical cutting properties, and weldability. However, the following points should be noted:

The cathode drop of thorium-tungsten is higher than that of cerium-tungsten.

At low voltages, cerium-tungsten has a longer lifespan than thorium-tungsten.

The minimum arc initiation voltage for cerium-tungsten is 12V, while for thorium-tungsten it is 30V.

Under the same cutting conditions, when the nozzle leaks water, the wear of thorium-tungsten is greater than that of cerium-tungsten.

Cerium-tungsten electrodes have lower work function and alpha radiation levels than thorium-tungsten electrodes and are non-radioactive.

In terms of electrode emission current density, cerium-tungsten produces a narrow, bright arc column with higher brightness and emission current density compared to thorium-tungsten.

3. Production Process

Preparation of Thorium-Tungsten Electrodes: Tungsten powder and thorium oxide powder are mixed in specific proportions, pressed, and sintered to produce thorium-tungsten rods. These rods are then subjected to rotary forging, wire drawing, straightening, cutting, and polishing to obtain the final thorium-tungsten electrodes.

Preparation of Cerium-Tungsten Electrodes: Cerium salt solution is added to tungsten oxide, dried, and calcined, followed by secondary reduction. The resulting tungsten-cerium powder is pressed into green rods, pre-sintered in a hydrogen molybdenum wire furnace, and then subjected to high-temperature electric sintering to form tungsten-cerium rods. These rods are subsequently hot rotary forged and drawn into the desired products.

4. Applications

Thorium-tungsten electrodes are typically used in direct current welding applications, requiring operation under high current conditions, with weldable materials including carbon steel, stainless steel, and copper-aluminum.

Cerium-tungsten electrodes are suitable for both direct current and alternating current welding applications, primarily used for welding materials such as carbon steel, stainless steel, silicon copper, copper, bronze, and titanium.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com