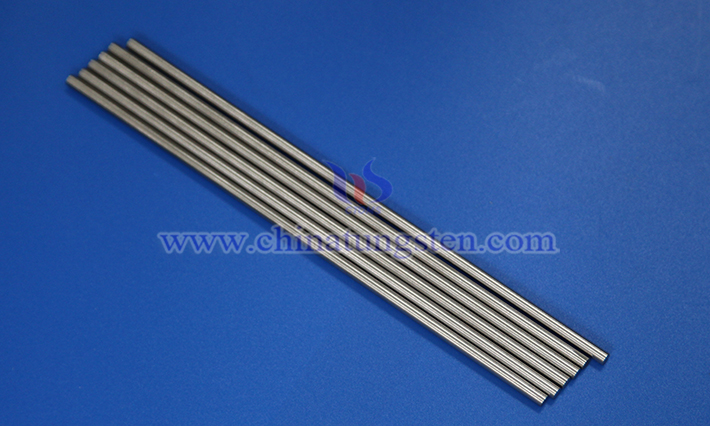

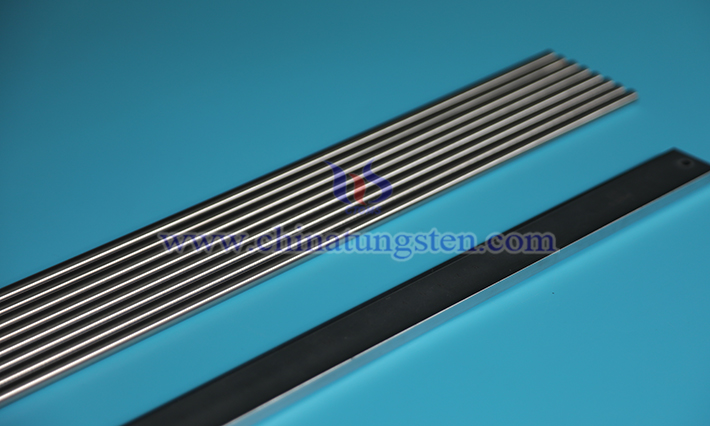

Tungsten-Rhenium Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 September 2025 14:23

Like tungsten-copper, tungsten-molybdenum, and tungsten-nickel-iron alloys, tungsten-rhenium alloy (W-Re) is a type of high-density tungsten-based alloy that combines the excellent properties of both metal tungsten and metal rhenium. It is widely used in aerospace, aviation, maritime, military, and defense fields. Below is the basic information about this alloy:

1. Definition

It is a solid-solution-strengthened alloy material made using powder metallurgy or melting methods, with refractory metal tungsten as the hard phase and metal rhenium as the binder phase. Generally, the rhenium content in the alloy is 3%, 5%, 10%, 25%, or 26%.

2. Performance

It exhibits a high melting point, high strength, high hardness, high ductility, high recrystallization temperature, high resistivity, high thermoelectric potential, low vapor pressure, low electron work function, and a low ductile-to-brittle transition temperature. Studies indicate that compared to pure tungsten, W-Re alloys offer higher resistivity and recrystallization temperature, along with improved mechanical properties, ductility, and weldability.

3. Classification

Based on rhenium content, it can be pided into low-content W-Re alloys (Re ≤ 5%) and high-content W-Re alloys (Re ≥ 15%).

Based on the preparation method, it can be categorized into melted W-Re alloys and powder metallurgy W-Re alloys.

Based on strengthening mechanisms, melted W-Re alloys can be further pided into solid-solution-strengthened W-Re alloys and precipitation-strengthened W-Re alloys; powder metallurgy W-Re alloys can be classified into solid-solution-strengthened W-Re alloys, dispersion-strengthened W-Re alloys, and precipitation-strengthened W-Re alloys.

4. Manufacturing

Preparation of doped tungsten-rhenium powder: Mix tungsten powder with an ammonium perrhenate solution to obtain a doped tungsten-rhenium impregnate, which is dried to yield doped tungsten-rhenium powder.

Reduction of the tungsten-rhenium mixed powder.

Pressing.

Pre-sintering.

Sintering to produce the alloy product. This method is simple to operate, ensures uniform rhenium distribution in the alloy, and results in good material consistency.

5. Applications

Used as filament materials in electron tubes, cathode ray tubes, and light bulbs, as well as grid wires and core metals for directly heated cathodes.

Employed as electrical contact materials, such as contacts in car horns, ignition contacts, voltage regulator contacts, telephone contacts, and various electrical switch contacts.

Used as thermocouple materials, primarily for temperature measurement in vacuum, reducing atmospheres, inert atmospheres, and high-temperature fields.

Applied as high-temperature-resistant materials, such as heat shields, rocket nozzle peripheral components, cone components, and coatings for engine or motor parts.

Utilized as wear-resistant materials, such as printer needles, pen tips, and center-of-gravity weights for surveying instruments.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com