Tungsten Alloy Ring

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2025 15:40

In daily life, as you pass by a machining workshop, you might catch a glimpse of a shiny metal ring on a robotic arm. Step into a medical device research lab, and you might find it quietly nestled within a critical piece of equipment. These rings, though seemingly ordinary, have a unique "heritage"—they are tungsten alloy rings.

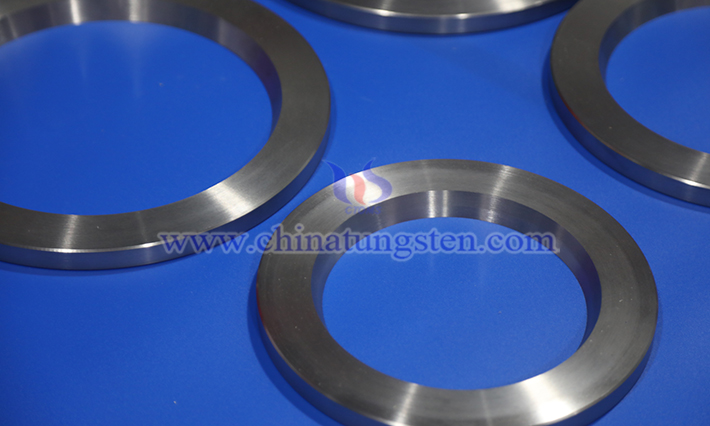

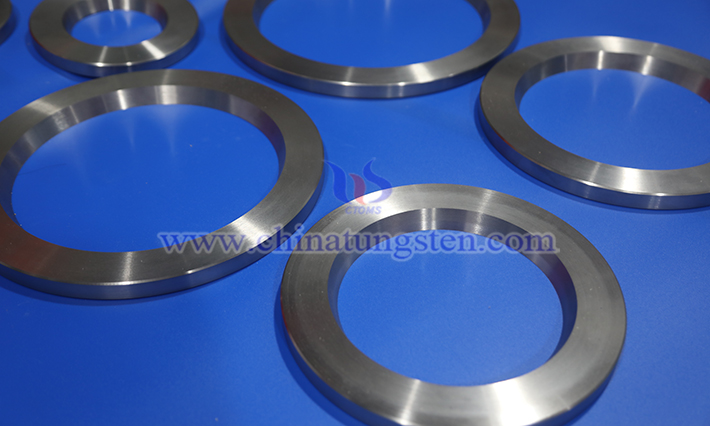

Upon first encountering a tungsten alloy ring, you’ll be drawn to its metallic sheen. It typically exhibits a silver-gray luster with a smooth, refined surface, resembling a meticulously crafted work of art. The ring’s uniform structure and solid build convey a substantial weight when held, sparking curiosity about its material and purpose.

I. Composition of Tungsten Alloy Ring

As the name suggests, tungsten alloy rings are primarily composed of tungsten, which typically accounts for over 85% of the material and is the key determinant of the ring’s basic properties. Tungsten, as a metal, boasts numerous standout characteristics. It has a high melting point of 3,422°C, enabling tungsten alloy rings to remain stable in high-temperature environments without melting or deforming. For instance, in mechanical components of high-temperature industrial furnaces, this property ensures stable operation and supports equipment reliability. Additionally, with a density ranging from 16.5 to 18.75 g/cm³, the high density allows the rings to maintain stability in environments subject to vibration or impact.

In addition to tungsten, other metals such as nickel, iron, cobalt, and copper are incorporated into the rings. These additives act as vital assistants, further optimizing the ring’s performance. Taking nickel and iron as examples, in W-Ni-Fe alloys, the addition of nickel and iron enhances the alloy’s ductility. When added in specific proportions, the alloy’s elongation can reach 15-30%, making the originally hard and brittle tungsten alloy more machinable. This allows the production of rings in various shapes and specifications to meet perse needs. In aerospace, where precision and complexity are paramount, these ductile tungsten alloy rings can be finely machined to fit various aircraft components. In W-Ni-Cu alloys, the inclusion of copper imparts non-magnetic properties and a low thermal expansion coefficient. When copper and nickel are blended in specific ratios, the alloy not only avoids interference in magnetically sensitive environments but also maintains dimensional stability under significant temperature fluctuations.

II. Characteristics of Tungsten Alloy Ring

High Hardness and Wear Resistance

In mechanical manufacturing, many components operate under prolonged friction, enduring continuous relative motion and wear, which demands high wear resistance from materials. Ordinary materials often degrade or fail due to wear and deformation, whereas tungsten alloy rings, with their excellent hardness, effectively resist friction-related wear, extending component lifespan. Their superior wear resistance reduces maintenance and replacement frequency, lowers operational costs, ensures long-term stability of mechanical systems, and prevents performance fluctuations caused by component wear.

High Density

With a density typically ranging from 16.5 to 18.75 g/cm³—over twice that of steel—tungsten alloy rings are an ideal choice for counterweights and shielding materials. They are widely used in aerospace, military equipment, and medical devices for balance weighting or radiation shielding.

Excellent Heat Resistance

Thanks to their high melting point and low thermal expansion coefficient, tungsten alloy rings maintain stable performance in high-temperature environments, resisting melting or deformation. Their low thermal expansion coefficient also minimizes dimensional changes in environments with significant temperature swings, preventing structural deformation or assembly gap issues. This ensures a consistent working state, enhancing the overall reliability of equipment operation.

Good Corrosion Resistance

Tungsten alloy rings exhibit strong chemical stability in corrosive media, effectively resisting the erosion of high-concentration strong acids in the chemical industry and the saline seawater in marine environments. This property allows them to serve reliably in corrosive settings, reducing equipment failure risks and improving the lifespan and safety of engineering equipment.

III. Applications of Tungsten Alloy Ring

In the medical industry, tungsten alloy rings play a significant role. In radiotherapy equipment, linear accelerators and gamma knives are essential for treating tumors. Tungsten alloy rings are used as collimators or shielding rings. Linear accelerators generate high-energy particle beams to destroy tumor cells, requiring precise control over beam direction and range. Acting as a "navigator," tungsten alloy ring collimators, with their high density and excellent machinability, guide the beams to the tumor site, minimizing damage to surrounding healthy tissues. In gamma knives, tungsten alloy rings serve as shielding rings, effectively blocking gamma ray leakage to protect medical staff and patients from radiation hazards, ensuring the safety of radiotherapy procedures.

Radiation detection sensors, critical in medical imaging and nuclear monitoring, also rely on tungsten alloy rings. Thanks to their excellent shielding properties against X-rays and gamma rays, which allow effective absorption and attenuation of radiation, they are commonly integrated into radiation detection sensors to ensure accurate radiation dose measurements in complex radiation environments.

In the aerospace sector, balancing weights for aircraft are crucial for flight stability and safety. In propeller aircraft, the high-speed rotation of propellers generates significant centrifugal forces, and imbalance can cause severe vibrations, compromising flight safety. Tungsten alloy rings, used as counterweight components, leverage their high density to provide substantial weight in a compact volume. By adjusting the position and weight of these counterweights, centrifugal forces are balanced, reducing vibrations and enhancing flight smoothness.

In aerospace electronic systems, electronic equipment must operate stably in complex electromagnetic and vibration environments. Tungsten alloy rings, with their high density and effective electromagnetic shielding properties, are employed as casings or shielding components. They block external electromagnetic interference, protecting electronic devices from disruptions. Additionally, their high density and stability resist vibration and impact during flight, ensuring the performance of electronic equipment remains unaffected and supporting the reliable operation of aerospace electronic systems.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com