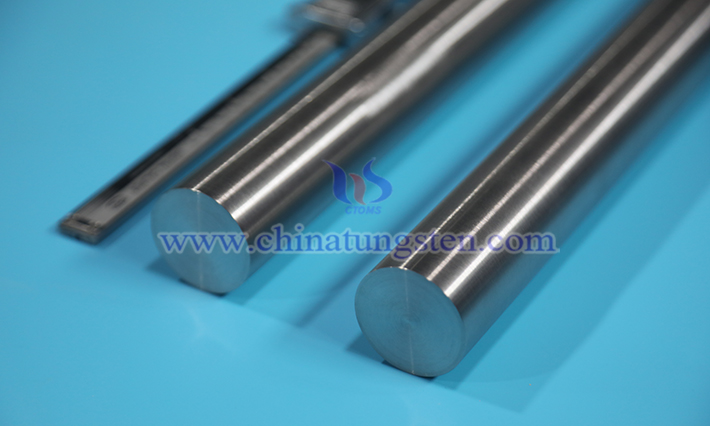

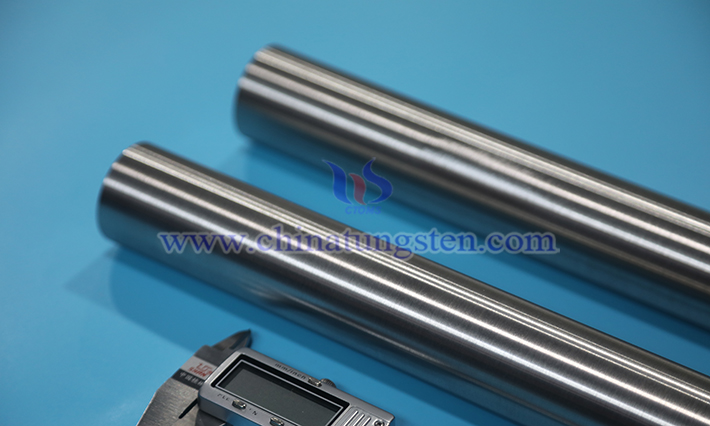

Tungsten Alloy Rod

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2025 15:35

In today’s era of rapid technological advancement, our lives are filled with a variety of high-tech products, from smartphones to advanced aerospace vehicles, all of which rely on a high-performance material—tungsten alloy rods—for stable operation. Though you may not often notice it in daily life, it plays a vital role in numerous critical fields.

I. Unveiling the Creation Process of Tungsten Alloy Rod

The birth of tungsten alloy rods is a testament to modern materials science and engineering technology, involving several precise and critical stages in their manufacturing process. They are primarily crafted from metal powders using specialized high-temperature powder metallurgy techniques.

The first step is the selection and preparation of raw materials. High-purity tungsten powder serves as the foundation. In addition to tungsten powder, a small amount of other metal powders, such as nickel, iron, copper, or cobalt, is added as a binder phase, typically comprising 5-10% of the mix. The inclusion of these binder metals not only improves the alloy’s formability and machinability but also significantly impacts its final physical and mechanical properties. For instance, nickel enhances the alloy’s toughness and processability, while iron boosts its strength.

The next step is the mixing process, where the selected tungsten powder and other metal powders are uniformly blended. Common methods include ball milling and mechanical alloying. During ball milling, the powders and grinding media rotate at high speed in a ball mill, achieving uniform mixing through mutual collision and friction. Throughout this process, oxygen content must be controlled to prevent oxidation during subsequent sintering, which could affect product quality.

Following mixing, the process moves to the forming stage. Mold pressing is a widely used method to shape the mixed powder into green compacts of the desired form. For parts with complex shapes, injection molding is more suitable. This technique involves mixing the powder with an appropriate binder to create an injectable material with good flowability, which is then injected into a mold cavity for shaping.

The green compacts then undergo sintering, a core process to enhance the density and mechanical properties of tungsten alloy rods. Liquid-phase sintering is a commonly employed method where, under high temperatures, the binder metals melt to form a liquid phase. This liquid phase facilitates the rearrangement and densification of tungsten particles, improving the alloy’s overall performance.

Throughout the production process, precise control of parameters such as temperature, pressure, and time is crucial, as any variation in these factors could lead to differences in the final product’s performance.

II. Revealing the Exceptional Properties of Tungsten Alloy Rod

High Melting Point: Tungsten alloy rods boast a high melting point, typically exceeding 3,370°C, enabling excellent performance in high-temperature environments. For example, in high-temperature furnaces used in metallurgy and glass manufacturing, where temperatures often surpass 1,000°C, ordinary metal materials would quickly soften or melt, failing to meet equipment needs. Tungsten alloy rods, with their high melting point, maintain stable physical form and mechanical properties under such conditions, ensuring reliable furnace operation.

Low Thermal Expansion Coefficient: The low thermal expansion coefficient of tungsten alloy rods makes them critical in precision instruments. In optical devices and electronic measuring equipment, where dimensional accuracy of components is paramount, ordinary materials may undergo size changes due to thermal expansion or contraction when temperatures fluctuate, affecting measurement precision and stability. With their low thermal expansion coefficient, tungsten alloy rods exhibit minimal dimensional changes within typical temperature ranges, helping precision instruments maintain high accuracy.

High Specific Gravity: With a specific gravity ranging from 16.5 to 18.75 g/cm³, tungsten alloy rods are widely used in counterweight applications. In aerospace, the distribution of an aircraft’s center of gravity is crucial for flight performance and stability. Installing tungsten alloy counterweights in strategic locations adjusts the center of gravity, ensuring optimal stability and control during flight. In the automotive industry, high-performance race cars use tungsten alloy counterweights to adjust vehicle balance, enhancing stability and handling at high speeds and through corners.

High Strength and Toughness: Tungsten alloy rods exhibit excellent mechanical properties, including high strength and toughness, making them vital in military and aerospace applications. In the military, the cores of armor-piercing projectiles are often made from tungsten alloy rods.

Good Machinability: Although tungsten itself has a high melting point and is challenging to machine, the addition of other metal elements and advanced powder metallurgy techniques has significantly improved the machinability of tungsten alloy rods.

Corrosion Resistance: Tungsten alloy rods demonstrate good resistance to most acids, alkalis, and salt solutions at room temperature, performing particularly well in non-oxidizing environments.

III. Applications of Tungsten Alloy Rod

In the military sector, tungsten alloy rods are undoubtedly a "star material," with their exceptional properties making them essential components of various military equipment. As the nemesis of tanks and armored vehicles, armor-piercing projectiles rely on tungsten alloy rods as their core. Modern tank-fired tungsten-core armor-piercing discarding sabot rounds leverage their high density and strength to concentrate immense kinetic energy at a single point upon high-speed impact, effectively penetrating enemy composite armor.

The electronics field is another key application area for tungsten alloy rods. In electron tubes, they are commonly used as electrode materials. As electrode materials, tungsten alloy rods offer good conductivity and corrosion resistance, withstanding high-speed electron impacts and high voltages within appropriate operating parameters, thus supporting the stable realization of electron transmission and signal amplification functions within electron tubes.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com