Cleaning of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:17

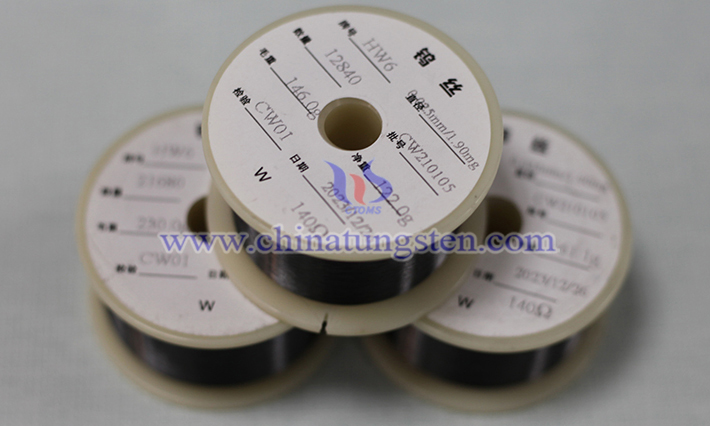

Tungsten wire is often used in glass heating equipment due to its high melting point and heat resistance, but long-term use will affect performance due to oxidation, contamination or residue accumulation. Cleaning of tungsten wire for glass heating is an important step to ensure heating efficiency and extend service life.

1. Safety Preparation: Be sure to disconnect the power supply before cleaning and ensure that the equipment cools to room temperature. Wear protective gloves and glasses to avoid tungsten wire breakage or chemical damage.

2. Preliminary Inspection: Observe the surface of the tungsten wire to confirm whether there is oxide, grease or glass residue. Minor contamination can be treated by physical methods, and severe contamination requires chemical cleaning.

3. Physical Cleaning: Use a soft brush or compressed air to gently remove surface dust and loose particles. Avoid scratching with hard objects to prevent damage to the surface of the tungsten wire. If necessary, use ultra-fine sandpaper (2000 mesh or more) to lightly grind and remove the slight oxide layer.

4. Chemical Cleaning: For stubborn stains, soak the tungsten wire in a diluted acid solution for several minutes to dissolve oxides or metal residues. The operation should be carried out in a fume hood and rinsed thoroughly with deionized water to prevent acid residues. Then wipe with ethanol or acetone to remove grease or organic matter.

5. Drying: The cleaned tungsten wire needs to be dried naturally in a dust-free environment or dried in a low-temperature oven to ensure that there is no moisture residue. Avoid high-temperature drying to prevent oxidation of the tungsten wire.

6. Inspection and Maintenance: After cleaning, check whether the tungsten wire has cracks or deformations. If so, replace it. Regular cleaning (every 1-3 months depending on the frequency of use) can maintain performance.

7. Notes: Tungsten wire is brittle and needs to be handled gently; ensure that there is no corrosive residue after chemical cleaning; the cleaning frequency and method should be adjusted according to the equipment use environment. Reasonable cleaning can significantly improve the glass heating efficiency and tungsten wire life.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com