The Principle of Tungsten Wire Heating Glass

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:32

The principle of tungsten wire heating glass is based on the scientific mechanism of electrothermal conversion and heat transfer. Its core is to efficiently convert electrical energy into thermal energy, and act on the glass through a specific heat transfer method to make it reach the temperature required for processing or molding. This process combines the characteristics of electrical energy, thermal energy and material science, and is widely used in glass manufacturing, light bulb production and industrial heat treatment.

1. Electrothermal Conversion: The Source of Heat

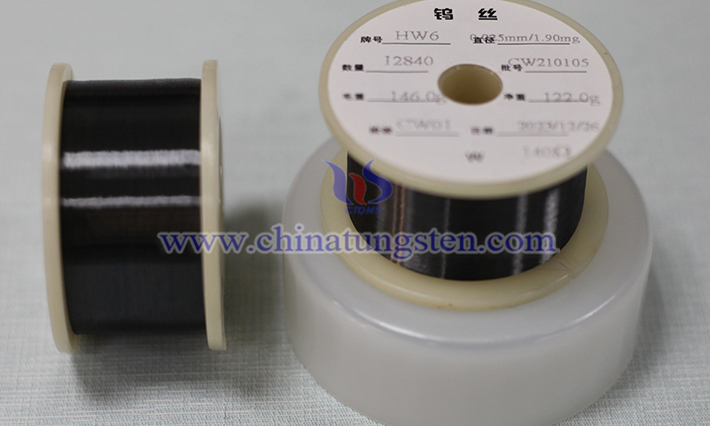

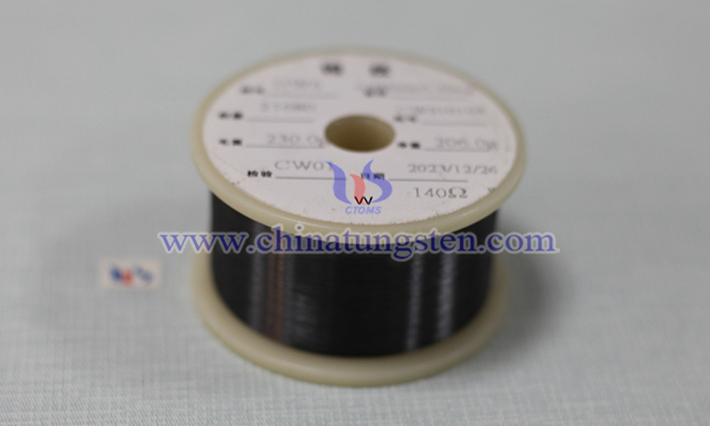

The core of tungsten wire heating lies in electrothermal conversion. When current passes through tungsten wire, tungsten wire will produce a significant resistance heating effect due to its high resistance characteristics. According to Joule's law (Q = I²Rt), electrical energy is quickly converted into thermal energy, causing the temperature of tungsten wire to rise sharply. As a high melting point metal (melting point up to 3422°C), tungsten can remain stable at extremely high temperatures and is not easy to melt or deform. Therefore, it is widely used in heating scenes that require high temperatures. The high temperature state of the tungsten wire provides sufficient energy basis for subsequent heat transfer, enabling it to efficiently transfer heat to the glass.

2. Heat Conduction: Direct Contact Heat Transfer

Heat conduction is an important way for tungsten wire to heat glass. When the tungsten wire is in direct contact with the glass surface, heat is transferred from the high-temperature tungsten wire to the lower-temperature glass through the vibration of molecules or atoms. This transfer method relies on direct contact between materials, and heat diffuses rapidly at the contact interface in the form of heat conduction. The efficiency of heat conduction is closely related to the contact area between the tungsten wire and the glass, the thermal conductivity of the material, and the temperature difference. In practical applications, tungsten wires are usually designed to fit tightly with the glass to ensure that heat can be quickly and evenly transferred to the glass surface, so that the temperature of the local area rises rapidly to a softened or molten state, meeting the needs of glass processing.

3. Thermal Radiation: Non-Contact Energy Transfer

In addition to heat conduction, thermal radiation is another key mechanism for tungsten wire to heat glass. High-temperature tungsten wires emit infrared radiation in the form of electromagnetic waves. These radiations can propagate at the speed of light and can act on the glass without a medium. Glass has a strong ability to absorb infrared rays and can convert the absorbed radiation energy into its own heat energy, thereby increasing the temperature. The significant advantage of thermal radiation is that it is suitable for non-contact heating scenarios. Even if there is a certain distance between the tungsten filament and the glass, heat can still be efficiently transferred through radiation. This method is particularly important in glass forming, annealing or special processes because it can achieve uniform heating and reduce material stress or deformation caused by direct contact.

4. Practical Applications and Characteristics

The principle of tungsten filament heating glass has shown the characteristics of high efficiency, precision and flexibility in practical applications. By precisely controlling the current size, the temperature of the tungsten filament can be adjusted, thereby achieving fine control of the glass heating process. Heat conduction is suitable for scenarios that require rapid local heating, such as glass cutting or sealing; while thermal radiation is more suitable for large-area or non-contact heating, such as glass shell forming in light bulb manufacturing. In addition, the high heat resistance and stability of tungsten filaments ensure the reliability of the equipment under long-term high-temperature operation.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com