Performance of Cut-Resistant Tungsten Wire Protective Gloves

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 April 2025 19:02

Cut-resistant tungsten wire protective gloves are a type of high-performance protective gear, primarily designed for work environments that require resistance to cutting, piercing, and abrasion risks. Tungsten wire, due to its exceptional strength and durability, is frequently used in manufacturing protective materials that demand superior cut resistance. The main performance characteristics of cut-resistant tungsten wire protective gloves are as follows:

1. Material Characteristics

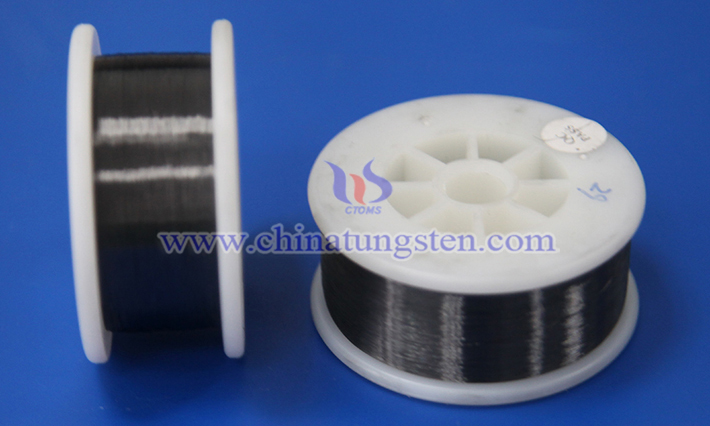

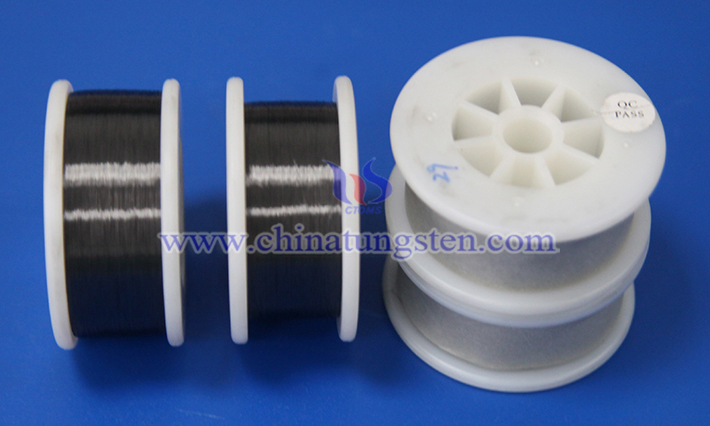

Tungsten wire is a filament material based on tungsten metal, boasting an extremely high melting point (approximately 3422°C) and excellent tensile strength. When woven or blended into the base materials of gloves—such as high-performance polyethylene (HPPE), aramid fibers, or nylon—it significantly enhances the gloves' protective capabilities. Compared to traditional cut-resistant materials, the hardness and toughness of tungsten wire make it more resistant to being severed by sharp objects. Additionally, its superior corrosion resistance and high-temperature tolerance ensure stable performance even in extreme conditions.

2. Cut Resistance

The core strength of cut-resistant tungsten wire protective gloves lies in their exceptional ability to withstand cuts. According to international standards (e.g., EN 388 or ANSI/ISEA 105), cut resistance is typically classified into multiple levels. Tungsten wire gloves often achieve high protective ratings (such as Level 5 under EN 388 or A5-A9 under ANSI), effectively resisting cuts from knives, glass shards, metal edges, and other sharp objects. This performance stems from the high density and molecular structure of tungsten wire, which prevents it from easily breaking or deforming under external force. For industries involving sharp tools—such as metalworking, glass manufacturing, or butchery—these gloves offer reliable safety assurance.

3. Abrasion Resistance and Durability

Beyond cut resistance, these gloves exhibit outstanding abrasion resistance. Tungsten metal’s extreme hardness (接近金刚石, close to diamond) ensures that the glove surface resists wear even after prolonged friction or contact with rough objects. This property extends the gloves’ service life, reducing the cost of frequent replacements. Furthermore, the high-temperature resistance of tungsten wire prevents melting or deformation in hot work environments (e.g., welding or thermal processing), further enhancing their durability.

4. Comfort and Flexibility

Although tungsten wire is inherently rigid, modern manufacturing techniques blend it with softer fibers (such as HPPE or nylon), significantly improving the gloves’ comfort and flexibility. High-quality tungsten wire gloves often employ seamless knitting technology, conforming to the hand’s natural curves and reducing fatigue during extended wear. Some products also feature nitrile rubber or polyurethane coatings on the palms and fingers, enhancing grip while maintaining breathability. This ensures users can handle precision tools with ease and flexibility.

5. Application Scenarios

Cut-resistant tungsten wire protective gloves are widely used across various high-risk industries. In construction and manufacturing, they shield workers from injuries caused by metal sheets or machinery parts. In food processing, they prevent accidental cuts from knives. In military or law enforcement settings, they offer protection against bayonets or sharp weapons. Additionally, their high-temperature resistance makes them suitable for scenarios involving contact with hot objects, such as metallurgy or firefighting operations.

6. Limitations

Despite their superior performance, tungsten wire protective gloves have some drawbacks. First, the inclusion of tungsten wire may increase the gloves’ weight and thickness, potentially reducing flexibility compared to standard cut-resistant gloves (e.g., HPPE gloves). Second, the high cost of tungsten metal results in a relatively expensive product, making it less suitable for low-budget applications. Lastly, if the coating design is suboptimal, prolonged use may lead to sweaty hands, affecting comfort.

Conclusion

While cost and weight may be considerations for some users, cut-resistant tungsten wire protective gloves are undoubtedly a worthwhile investment for professional fields requiring top-tier protection. CTIA GROUP’s tungsten wire offers excellent cut resistance, abrasion resistance, and high-temperature tolerance. For specific product inquiries, please contact CTIA GROUP at: sales@chinatungsten.com.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com