Cut-Resistant Tungsten Wire for Stone Processing

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:42

In the modern stone processing industry, efficient, precise, and durable cutting tools are crucial for improving production efficiency and product quality. With continuous technological advancements, cut-resistant tungsten wire has emerged as a high-performance material, gaining prominence in the field of stone processing. Renowned for its exceptional physical properties and chemical stability, tungsten wire has become an ideal choice for cutting hard stone materials. This article explores the characteristics, applications, and significance of cut-resistant tungsten wire in stone processing.

1. Characteristics of Cut-Resistant Tungsten Wire

Tungsten is a rare metal with an extremely high melting point (approximately 3,422°C) and remarkable hardness, allowing tungsten wire to maintain stability under high-temperature and high-pressure conditions. Compared to traditional steel wires or diamond wires, tungsten wire excels in wear resistance and tensile strength. Furthermore, its chemical inertness prevents corrosion, enabling prolonged use even in humid or acidic environments. These attributes collectively provide tungsten wire with unparalleled advantages in stone processing.

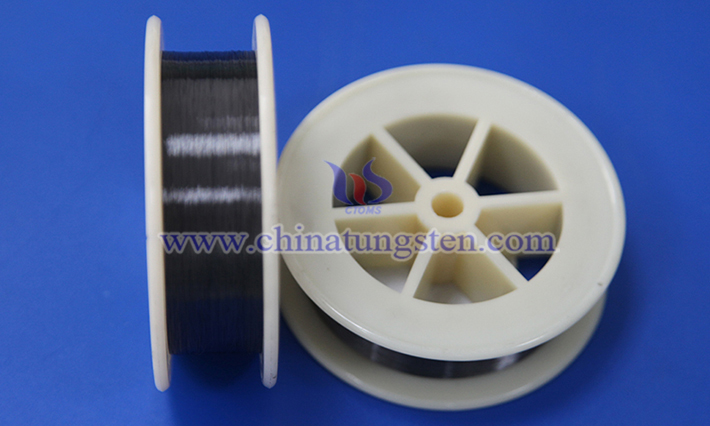

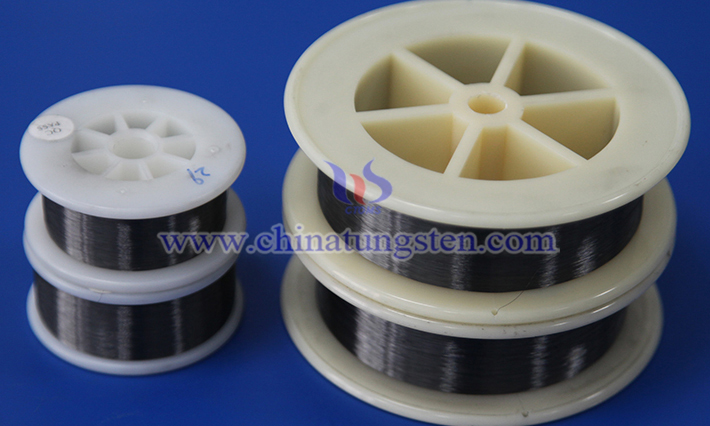

Another notable feature of tungsten wire is its fine diameter and high precision. Modern manufacturing techniques can draw tungsten wire to a micron-level thickness, enhancing cutting accuracy and reducing material waste. This precision is particularly vital for stone products requiring complex shapes or intricate carvings.

2. Applications of Cut-Resistant Tungsten Wire in Stone Processing

In the stone processing sector, cut-resistant tungsten wire is primarily used in wire saw cutting equipment. Traditional stone cutting often relies on diamond blades or steel cables, but these tools tend to wear out quickly and exhibit low efficiency when handling ultra-hard stones such as granite or basalt. The introduction of tungsten wire cutting technology effectively addresses these challenges.

Take granite cutting as an example: tungsten wire saws, through high-speed movement and sustained tension, gradually divide the stone. Compared to diamond wires, tungsten wire offers greater durability, with slower performance degradation during prolonged continuous operations. This reduces the frequency of tool replacements and minimizes downtime, thereby boosting overall production efficiency. Additionally, tungsten wire produces smoother cuts, alleviating the burden of subsequent polishing processes, which is especially beneficial for high-end stone product manufacturing.

Beyond flat cutting, tungsten wire is widely applied in processing irregularly shaped stone products. For instance, in crafting stone carvings, columns, or curved decorative pieces, the flexibility and high strength of tungsten wire effortlessly handle complex geometries, ensuring the precision and aesthetics of the finished product.

3. Significance and Prospects of Cut-Resistant Tungsten Wire

The advent of cut-resistant tungsten wire has not only revolutionized stone processing technology but also delivered dual economic and environmental benefits to the industry. First, its durability significantly lowers tool replacement costs, enabling businesses to achieve higher output with less investment. Second, the cutting process with tungsten wire generates less dust and waste compared to traditional methods, making it more environmentally friendly and aligning with current trends in green manufacturing.

Looking ahead, as manufacturing techniques for tungsten wire continue to improve—such as enhancing toughness through doping with other elements or developing advanced coating technologies—its application prospects in stone processing will become even broader. Meanwhile, with the widespread adoption of smart manufacturing and automated equipment, tungsten wire cutting technology is poised to integrate deeply with CNC systems, enabling more efficient and intelligent production models.

In conclusion, cut-resistant tungsten wire, with its high strength, wear resistance, and precision, has become an indispensable tool in the stone processing industry. It not only enhances processing efficiency and product quality but also injects new vitality into the sector’s sustainable development. Driven by ongoing technological advancements, the scope and performance of tungsten wire applications will continue to expand, bringing even greater possibilities to stone processing.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com