Stab-Proof Vests Using Cut-Resistant Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:33

Stab-proof vests, as a vital piece of personal protective equipment, are widely used by law enforcement officers, military personnel, security guards, and individuals in high-risk occupations. Their primary function is to defend against stabbing, slashing, and chopping attacks from sharp implements such as knives and daggers.

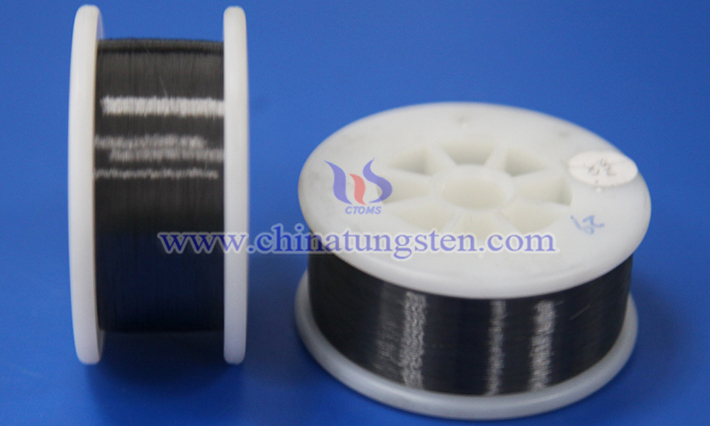

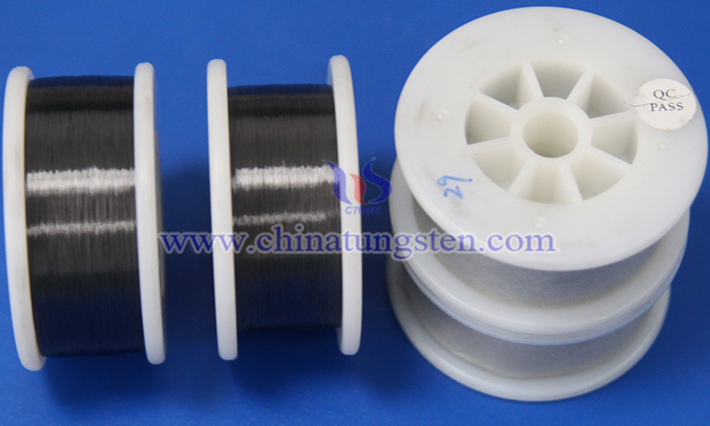

Tungsten is a metal renowned for its high melting point, high density, and exceptional hardness. Its tensile strength and wear resistance rank among the best of many materials. Tungsten wire, a thin, elongated strand of tungsten metal produced through specialized processes, not only inherits these superior properties but also offers a degree of flexibility. Cut-resistant tungsten wire builds upon these qualities, exhibiting even greater resistance to cutting and abrasion. This characteristic makes it theoretically ideal for enhancing the materials used in stab-proof vests.

Traditional stab-proof vests typically utilize high-strength fibers such as ultra-high-molecular-weight polyethylene (UHMWPE) and aramid (Kevlar), which are celebrated for their lightweight nature, cut resistance, and impact resistance. However, when faced with sharper or more penetrating attacks, these fibers may reveal certain limitations. The incorporation of tungsten wire can significantly improve the material’s resistance to cutting and penetration, particularly excelling in defending against high-speed or high-intensity assaults from sharp objects.

Specifically, the high hardness of cut-resistant tungsten wire makes it difficult for ordinary blades to slice or sever it, while its heat-resistant properties ensure stability even in extreme environments. Furthermore, the small diameter and weaveability of tungsten wire allow it to be integrated into the protective layers of stab-proof vests as a composite material. This creates a structure that combines flexibility with exceptional protective capabilities. Such a design not only enhances overall defense but also enables localized reinforcement in critical areas like the chest and back, providing more comprehensive safety.

In practical applications, cut-resistant tungsten wire can be incorporated into stab-proof vests in various forms. The most common method involves weaving technology, where tungsten wire is blended with other high-strength fibers to create a protective fabric. This fabric retains the lightweight comfort of fiber materials while leveraging tungsten wire to boost cut resistance. Another approach is to use tungsten wire as a reinforcing layer, embedded within a multi-layered composite structure alongside soft substrates and high-hardness panels, forming a protective system that balances flexibility and rigidity. Additionally, tungsten wire can be combined with other stab-resistant materials through coating or lamination processes, further optimizing the vest’s overall performance.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com