Cut-Resistant Tungsten Wire for Glass Processing

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:37

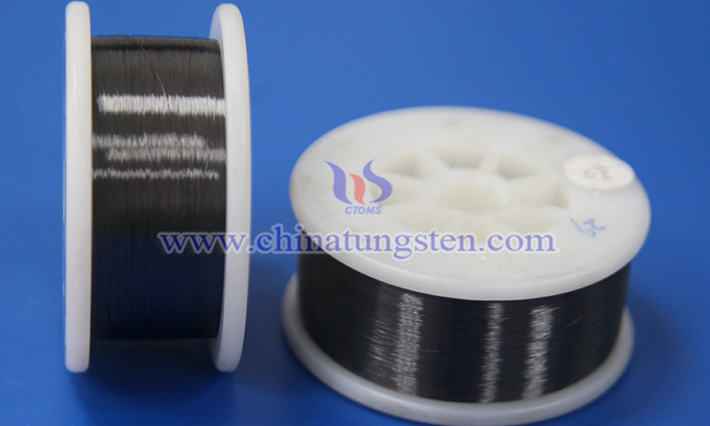

Tungsten (W) is a rare metal with an exceptionally high melting point and hardness. Its unique properties make it an ideal choice for high-precision and high-durability processing tasks. Cut-resistant tungsten wire is a fine, wire-like tool primarily made from tungsten metal. Due to its outstanding physical and chemical properties, it holds a significant position in the field of glass processing.

In the glass processing industry, cut-resistant tungsten wire is commonly used for cutting or assisting in processing techniques, meeting a wide range of needs from ordinary glass to specialty glass. As modern industry demands increasingly higher precision and complexity in glass products, the application scope and importance of cut-resistant tungsten wire continue to expand.

I. Superior Characteristics of Cut-Resistant Tungsten Wire:

1. High Melting Point and Heat Resistance: Tungsten has a melting point of 3,422°C, one of the highest among naturally occurring metals. This allows tungsten wire to maintain structural stability in the high-temperature environments of glass processing, resisting melting or deformation. It is highly suitable for cutting molten glass or heat-based processing techniques.

2. Excellent Tensile Strength: Tungsten wire exhibits exceptional tensile strength, retaining sufficient toughness and durability even when drawn into extremely fine diameters. This is particularly crucial for precision glass cutting, ensuring stability and consistency in cutting lines.

3. Corrosion Resistance and Chemical Stability: Tungsten demonstrates good corrosion resistance at both room and elevated temperatures, withstanding acidic or oxidative environments encountered during processing, thus extending its service life.

4. Ultra-Fine Processing Capability: Through advanced wire-drawing techniques, tungsten wire can achieve diameters at the micrometer level. This ultra-fine property enables high-precision glass cutting, making it especially applicable to fields requiring extreme accuracy, such as optical glass and display screen glass.

5. High Surface Smoothness: With special treatment, tungsten wire achieves an exceptionally smooth surface, minimizing damage to glass surfaces during cutting and ensuring the quality of the finished product.

II. Main Application Scenarios of Cut-Resistant Tungsten Wire in Glass Processing:

1. Precision Glass Cutting: In the production of glass products such as smartphone screens, tablet displays, or optical lenses, tungsten wire is often used as a wire-cutting tool. When paired with precision equipment, it can produce glass sheets with uniform thickness and smooth edges, meeting high-precision requirements. This technique is particularly common in processing thin glass (less than 1 mm thick).

2. Functional Glass Manufacturing: In certain specialty glass products, such as laminated glass or smart glass, tungsten wire is embedded and electrified for heating purposes, enabling functions like defrosting, defogging, or dimming.

3. Laboratory and Research Applications: During the development of glass materials, tungsten wire is frequently used for experimental cutting or high-temperature testing, assisting researchers in exploring the properties and processing methods of new glass types.

4. Cross-Industry Applications: Beyond glass processing, cut-resistant tungsten wire is widely utilized in the semiconductor industry, aerospace sector, and high-temperature welding processes, further highlighting its versatility and value.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com