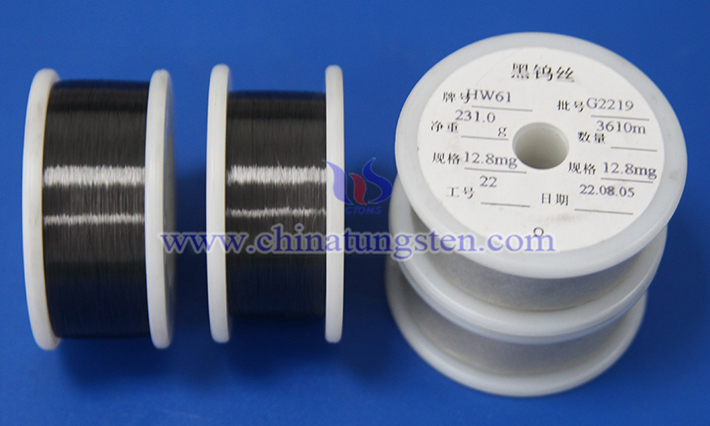

Cut-Resistant Tungsten Wire for Protective Clothing

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:30

Cut-resistant tungsten wire is a material characterized by high strength, high hardness, and excellent heat resistance. Due to its outstanding physical properties, it is frequently utilized in the production of protective clothing, particularly for gear designed to withstand cutting, piercing, or high-temperature environments.

Tungsten itself is renowned for its high density and extraordinarily high melting point (reaching 3,422°C), enabling tungsten wire to endure extreme heat while offering remarkable resistance to cutting and piercing. Through modern textile techniques and precision processing, cut-resistant tungsten wire can be woven into high-density mesh structures or combined with other high-performance fibers (such as Kevlar or ultra-high-molecular-weight polyethylene) to create various types of protective clothing. These include, but are not limited to, protective gloves, aprons, and full-body suits, which are extensively used in industrial settings, law enforcement, military tasks, and other high-risk environments.

In the realm of industrial protection, the application of cut-resistant tungsten wire stands out prominently. For instance, in industries like metalworking, glass manufacturing, or woodworking, workers are often exposed to sharp tools, high-speed flying debris, or jagged edges. Traditional protective materials may fall short in countering these hazards, whereas a tungsten wire-based protective layer significantly reduces the risk of cuts or punctures. Moreover, thanks to refinement processes that preserve a degree of flexibility, workers wearing such protective clothing can still operate tools with agility, enhancing both efficiency and safety. The high wear resistance of tungsten wire also extends the lifespan of protective gear, cutting down on the costs associated with frequent replacements.

In law enforcement and military contexts, cut-resistant tungsten wire demonstrates unique advantages. For example, stab-proof vests and cut-resistant gloves are critical equipment for police officers or special forces during missions. While conventional stab-resistant materials may struggle against sharp weapons (such as daggers or ice picks), the high hardness and toughness of tungsten wire effectively neutralize such threats, safeguarding the wearer’s life. Additionally, ongoing efforts to unlock the lightweight potential of tungsten wire—through optimized weaving and composite techniques—enable manufacturers to reduce equipment weight while maintaining protective performance, thereby improving wearer comfort.

Beyond its cut-resistant capabilities, the high melting point of cut-resistant tungsten wire also excels in high-temperature environments. In scenarios like firefighting or welding, protective clothing must not only block flames and heat but also possess sufficient mechanical strength to handle complex conditions. The inclusion of tungsten wire ensures that the gear maintains structural integrity under extreme circumstances while offering additional thermal insulation to the wearer. This multifunctionality positions tungsten wire as a vital component in the design of high-end protective equipment.

Despite its numerous benefits, the application of cut-resistant tungsten wire has certain limitations. For example, prolonged exposure to extreme acidic or alkaline environments or corrosive chemicals may degrade its performance, necessitating careful selection and maintenance based on specific conditions. Furthermore, the relatively high production cost of tungsten wire limits its widespread adoption in lower-end markets.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com