The Secret of Smart Photochromic Glass: the Magic of Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 15:32

Smart color-changing glass is like a magical wizard, capable of automatically adjusting its color and transparency based on environmental changes such as light intensity, temperature, or electric field variations. This allows it to regulate indoor light and temperature, achieving goals like energy saving, emission reduction, and enhanced comfort. On scorching summer days, it can block intense sunlight, reducing the load on indoor air conditioning. In the cold of winter, it allows ample sunlight to stream in, adding warmth to the interior.

The "family" of smart color-changing glass is perse, and based on different color-changing mechanisms, it is primarily categorized into photochromic glass, thermochromic glass, and electrochromic glass. Today’s protagonist, electrochromic glass, is a "chameleon" that obeys the commands of electrical signals. It alters its optical properties through an applied electric field, achieving changes in color and transparency. Its structure is relatively complex, resembling a meticulously constructed "miniature city," typically composed of a transparent conductive layer, an electrochromic layer, an electrolyte layer, and an ion storage layer.

The outermost transparent conductive layer serves as the "traffic artery" of this city, conducting electricity to power the entire color-changing process. It is usually made from materials like indium tin oxide (ITO) or aluminum-doped zinc oxide (AZO), ensuring both excellent conductivity and the smooth passage of light.

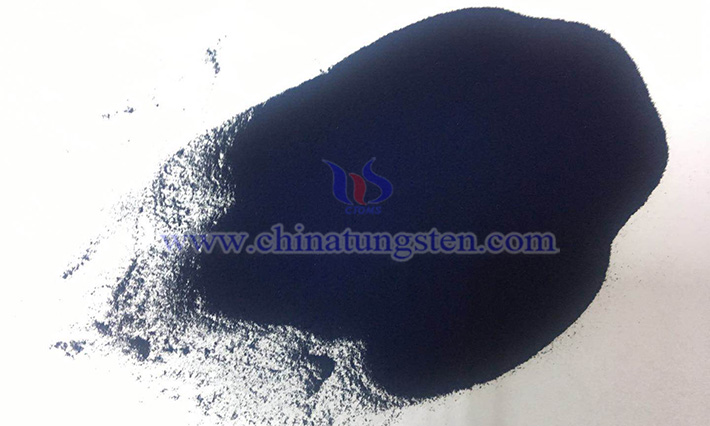

The electrochromic layer is the core "color-changing factory," where redox reactions occur under the influence of an electric field, altering the material’s optical properties and enabling the glass to change color. Common electrochromic materials include tungsten oxide (WO₃) and nickel oxide. Take tungsten oxide, for example: driven by an electric field, it can absorb or release ions, changing its valence state and displaying different colors accordingly.

The electrolyte layer acts as an "ion highway," responsible for conducting the ions needed during the color-changing reaction, ensuring swift and smooth movement of ions between layers.

The ion storage layer is akin to an "ion warehouse," storing and supplying the ions required for color changes while maintaining the system's ionic balance. When an electric field is applied, ions from the storage layer travel through the electrolyte layer into the electrochromic layer, reacting with the electrochromic material to produce a specific color. By controlling the strength and direction of the electric field, the quantity and speed of ions entering the electrochromic layer can be precisely adjusted, allowing fine-tuned control over the glass’s color depth and transparency. When the electric field is removed, the ions return from the electrochromic layer to the ion storage layer, restoring the glass to its initial state.

I. Tungsten Oxide Takes the Stage: The Core Force of Electrochromism

In the "color-changing factory" of electrochromic glass, tungsten oxide stands out as the undisputed "star." CTIA GROUP LTD’s WO₃ is a transition metal oxide with a unique crystal structure and electronic properties. In the field of electrochromism, it shines as a key material for achieving efficient color changes due to its exceptional capabilities.

When an electric field is applied to electrochromic glass, it’s as if a "color-changing command" is issued to tungsten oxide. WO₃ undergoes a remarkable transformation. Taking lithium ions (Li⁺) as an example, under the electric field’s influence, Li⁺ ions depart from the ion storage layer, swiftly traveling along the "ion highway" of the electrolyte layer into the electrochromic layer. Here, Li⁺ meets WO₃ and triggers a reduction reaction, represented by the chemical equation: WO₃ + xLi⁺ + xe⁻ ⇌ LiₓWO₃. As lithium ions embed into the tungsten oxide lattice, its valence state changes, altering its light absorption and scattering properties, resulting in different colors on the glass. When a reverse electric field is applied, the lithium ions are extracted from LiₓWO₃, returning to the ion storage layer, and the glass gradually becomes transparent again. By precisely controlling the electric field’s strength, direction, and duration, the amount of lithium ions entering or exiting WO₃ can be flexibly adjusted, enabling meticulous regulation of the glass’s color and transparency.

CTIA GROUP LTD’s tungsten oxide boasts a high optical modulation rate, meaning it can significantly alter the glass’s light transmission during the color-changing process. From a transparent state to a darkened state, WO₃ can drastically reduce the glass’s transmittance, effectively blocking visible light and infrared rays from sunlight, thus minimizing indoor heat gain and glare. This outstanding optical performance makes electrochromic glass excel in building energy efficiency and indoor comfort enhancement.

Additionally, CTIA GROUP LTD’s tungsten oxide offers excellent cyclic stability. During repeated cycles of color-changing and fading under an electric field, WO₃ maintains robust structural stability and electrochemical reactivity, resisting performance degradation. This means that glass using WO₃ as an electrochromic material enjoys a long service life, consistently delivering stable color-changing functionality over years of use without frequent replacement, significantly reducing operational and maintenance costs. Whether in the curtain walls of high-rise buildings or the windows of cars and airplanes, WO₃-based electrochromic glass provides a reliable, efficient, and smart dimming experience.

II. How Tungsten Oxide Works Its Magic

In the intricate system of electrochromic glass, CTIA GROUP LTD’s tungsten oxide excels in achieving color-changing functionality thanks to the synergistic transport of ions and electrons, as well as seamless coordination with other layers.

At the microscopic level, when an electric field is applied to the glass, the electrochromic process unfolds like a precisely choreographed "microscopic dance." Lithium ions (Li⁺), the key "dancers" in this performance, are directed by the electric field to move from the ion storage layer, swiftly traversing the electrolyte layer. The ion channels within the electrolyte layer act like tailored "highways" for Li⁺, ensuring high-speed and efficient movement. Upon entering the electrochromic layer and encountering WO₃, the ensuing reduction reaction is more than a simple chemical bond—it’s a "feast" of electron transfer. Electrons (e⁻) join the process, embedding into the WO₃ lattice alongside lithium ions. This electron transfer alters the electron cloud distribution of the atoms in WO₃, affecting its ability to absorb and scatter different wavelengths of light. It’s as if WO₃ dons a "coat" of varying colors, causing the glass to exhibit corresponding color changes.

The synergy between CTIA GROUP LTD’s tungsten oxide, the transparent conductive layer, and the ion storage layer is also critical. The transparent conductive layer, as the conductor of electric current, serves as an "energy hub," providing a steady power supply to the entire color-changing system. When an external power source is connected, it distributes current evenly across the electrochromic area, delivering the energy needed for WO₃’s color-changing reaction. Without the efficient conductivity of this layer, the electric field couldn’t be uniformly applied to WO₃, rendering the color-changing process unstable or even impossible.

The ion storage layer acts as a "solid backbone" for WO₃’s color changes. It not only supplies the lithium ions required for WO₃’s transformation but also promptly accepts ions extracted from WO₃ under a reverse electric field, maintaining the ionic balance of the electrochromic system. If electrochromic glass were an ecosystem, the ion storage layer would be its indispensable "resource reservoir." Should this layer falter—due to insufficient ion storage or impeded ion release—WO₃’s color-changing performance would suffer, potentially preventing the glass from fully transitioning between states and affecting its effectiveness.

In practical applications, optimizing WO₃’s preparation process, structure, and interfacial properties with other layers can further enhance electrochromic glass performance. For instance, using nanostructured WO₃ increases its specific surface area, providing more reactive sites and accelerating ion insertion and extraction, thus shortening response times. Improving the ion conductivity of the electrolyte layer and the ion storage capacity of the ion storage layer enhances system stability and durability. These advancements, rooted in a deep understanding of WO₃’s role in electrochromic glass, allow its "magic" to be performed with even greater perfection.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com