Applications of Cutting-Resistant Tungsten Wire in the Industrial Sector

- Details

- Category: Tungsten Information

- Published on Monday, 10 March 2025 19:21

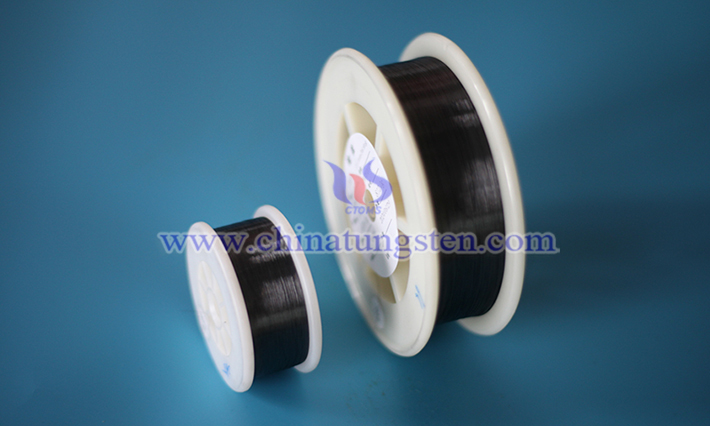

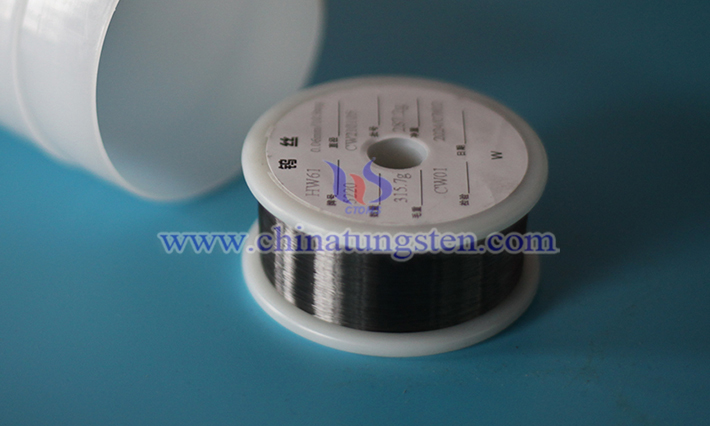

Tungsten wire with high cutting resistance (i.e., tungsten wire with excellent durability against cutting) plays a significant role in industrial applications requiring high precision and durability, thanks to its high strength, heat resistance, and corrosion resistance. Its applications span from precision manufacturing to heavy industry, making it an indispensable material in modern industrial settings. Below are some of the primary applications of cutting-resistant tungsten wire in the industrial sector:

1. Electrical Discharge Machining (EDM)

Cutting-resistant tungsten wire is commonly used as an electrode wire in EDM, a precision machining technique that removes material through electrical spark discharges. This method is widely applied in mold manufacturing, aerospace component processing, and similar fields. The high strength and heat resistance of tungsten wire make it exceptional for high-speed cutting and processing complex shapes, particularly when cutting hard materials like titanium alloys or high-temperature alloys.

2. Semiconductor Industry

In semiconductor manufacturing, cutting-resistant tungsten wire is employed for wafer slicing or the processing of precision components. Its fineness and wear resistance enable it to cut brittle materials like silicon wafers while maintaining high precision and minimal material loss.

3. Medical Device Manufacturing

Due to its biocompatibility and high strength, tungsten wire is often used in the production of surgical tools or minimally invasive medical devices. For instance, in the manufacturing of Treasured scopes or catheters, cutting-resistant tungsten wire can be used to cut or shape tiny components.

4. Lighting and Electronics Industry

While traditional tungsten wire is commonly associated with incandescent lamp filaments, in modern industry, cutting-resistant tungsten wire is also used to produce specialized electronic components or wiring materials for high-temperature environments. Its heat resistance and tensile strength make it ideal for use in vacuum tubes or high-temperature furnaces.

5. Aerospace and Defense

In the aerospace sector, cutting-resistant tungsten wire is utilized in the production of heat-resistant and wear-resistant components. For example, in the processing of turbine blades or propulsion systems, tungsten wire can be used for precision cutting or as a reinforcing material in composites.

6. Metal and Composite Material Cutting

Cutting-resistant tungsten wire is also employed as a component of wire saws in industrial cutting equipment, used to slice metal blocks, ceramics, or composite materials. Its high wear resistance and fracture resistance ensure stability during prolonged operations.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com