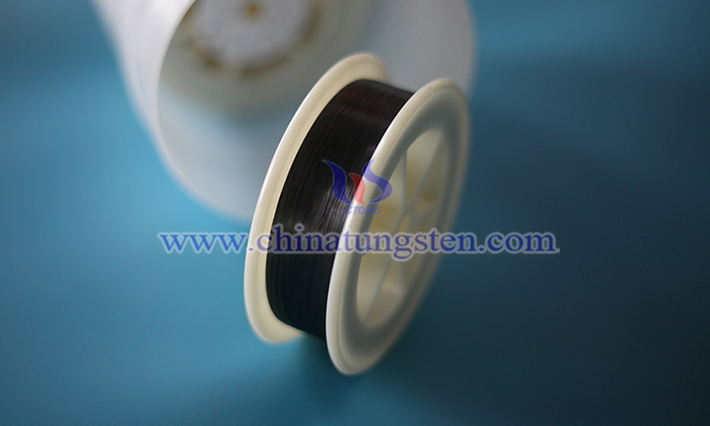

Applications of Cut-Resistant Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 10 March 2025 19:10

Cut-resistant tungsten wire is widely used across various industries due to its exceptional tensile strength, high-temperature stability, and capability for ultra-fine diameter processing. Below are its primary applications:

1. Industrial Manufacturing & Processing

Core Material for Cutting Tools: Directly used as cutting wires in wire-cut machines (e.g., electrode wires in electrical discharge machining) for precision cutting of high-hardness materials like metals and ceramics.

Guiding Wires for Grinding Equipment: Guides abrasive materials in precision grinding or polishing equipment, extending service life with superior wear resistance.

Wear-Resistant Mechanical Components: Woven into high-strength, wear-resistant mesh for screening equipment (e.g., mining vibratory screens) or anti-tear layers in conveyor belts.

2. Safety Protection Equipment

Cut-Resistant Gloves: High-density tungsten wire mesh layers crafted via specialized weaving techniques, used in industrial and firefighting fields to resist knives or sharp objects.

Anti-Stab Fabrics: Combined with Kevlar fibers to create stab-resistant suits or blast blankets, enhancing defense against sharp threats.

Industrial Protective Mesh: Used as guards or barriers for machinery to withstand impacts from flying debris.

3. Automotive & Aerospace

Tire Puncture-Resistant Layers: Woven into mesh structures embedded in tire sidewalls or treads to improve cut and puncture resistance (e.g., off-road vehicle tires).

Aerospace Cable Reinforcement: Serves as reinforcement for high-temperature cables in aircraft engine environments, protecting wires from heat and wear.

Transmission System Components: Directly integrated into high-load transmission chains or cables to reduce friction-induced breakage risks.

4. Medical Field

Minimally Invasive Surgical Instruments: Used to create high-strength surgical sutures or endoscopic guide wires, offering both corrosion resistance and flexibility.

Orthopedic Traction Wires: High-strength wires for bone fixation or traction in orthopedic surgeries.

5. Electronics & Semiconductors

Precision Wire Cutting: Ultra-fine tungsten wire (micron-level diameter) for cutting semiconductor wafers, sapphire glass, and other brittle materials.

High-Temperature Environment Wires: Acts as conductive wires in vacuum or high-temperature furnaces, combining heat resistance and mechanical durability.

6. Military & Defense

Armor Reinforcement Layers: Woven into mesh and embedded in composite armor to enhance bullet or shrapnel interception capabilities.

Military Vehicle Protective Mesh: Used as external vehicle shielding to resist impacts from improvised explosive device (IED) fragments.

7. Sports & Outdoor Equipment

High-Performance Fishing Lines: Ultra-durable saltwater fishing lines or deep-sea cables resistant to fish teeth or reef abrasion.

Climbing Rope Cores: Integrated as internal reinforcement in ropes to improve cut and wear resistance.

8. Energy & Heavy Industry

Mining Screens: Woven directly into wear-resistant screens for ore sorting or crushing equipment.

Nuclear Industry Components: Used as radiation-resistant, high-temperature measurement or control cables in nuclear reactors.

9. Emerging Technologies

Micro-Robot Drive Wires: Utilized for their strength and flexibility as transmission or load-bearing components in micro-mechanical arms.

Space Exploration Equipment: Extreme-environment-resistant cables or structural parts for lunar or Mars rovers.

10. Future Trends

Flexible Wearable Devices: Integrated with flexible materials to develop smart protective clothing with both safety and comfort.

Micro-Electromechanical Systems (MEMS): Used as support structures or conductive wires in micron-level sensors.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com