Manufacturing Process of Halogen Lamp Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 March 2025 17:20

Halogen lamps are high-efficiency and long-lasting light sources, widely used in home lighting, automotive headlights, and stage lighting. One of their core components is tungsten wire, which plays a critical role in the high-temperature environment inside the lamp.

The manufacturing process of tungsten wire is complex and generally involves the following key steps:

1. Tungsten Powder Preparation

The raw material for tungsten wire is high-purity tungsten powder, which directly affects the final properties of the tungsten wire. Tungsten powder is typically prepared using the hydrogen reduction method, in which ammonium paratungstate or sodium tungstate reacts with hydrogen to produce tungsten powder. This process requires strict control of hydrogen concentration and reaction temperature to ensure the purity and uniformity of the tungsten powder.

2. Tungsten Powder Forming

Once the tungsten powder is prepared, it must be shaped into tungsten rods or bars through forming techniques. Common forming methods include pressing and extrusion.

Pressing: Tungsten powder is mixed with a binder and compressed into the desired shape using high pressure.

Extrusion: The tungsten powder is heated and extruded into thin rods or fine wires.

The formed tungsten rods or bars then undergo a sintering process to remove binders and enhance their density and mechanical strength.

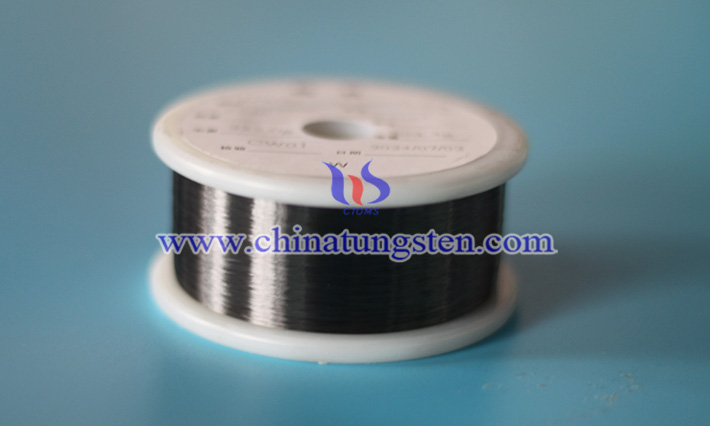

3. Wire Drawing Process

Wire drawing is one of the most critical steps in tungsten wire manufacturing. During this process, tungsten rods or bars are drawn into fine wires by gradually reducing their diameter. Temperature, drawing speed, and cooling rate must be carefully controlled to ensure uniform wire thickness and high mechanical strength. The wire drawing process significantly affects the tungsten wire’s mechanical properties, surface finish, and resistance to breakage.

4. Annealing Treatment

After wire drawing, tungsten wire typically undergoes annealing to relieve internal stresses and improve its toughness and ductility. The control of annealing temperature and duration directly impacts the mechanical properties and electrical conductivity of the tungsten wire. Since halogen lamp tungsten wire must endure repeated heating and cooling cycles, precise annealing control helps enhance its lifespan and high-temperature resistance.

5. Surface Treatment

To improve the corrosion resistance and oxidation resistance of tungsten wire, surface treatment is necessary. Common surface treatment methods include:

Oxidation Treatment: A stable oxide layer forms on the tungsten wire surface, effectively preventing further oxidation.

Coating Treatment: A thin protective film or a halogen gas mixture is applied to further enhance the oxidation resistance and corrosion resistance of the tungsten wire.

6. Precision Cutting and Shaping

Tungsten wire must be cut precisely to ensure proper installation inside the lamp. The length, bending, and shape of the wire must meet design specifications, requiring high-precision cutting and shaping equipment during production. Additionally, to enhance stability, the wire may undergo a series of quality inspections after cutting to ensure it meets industry standards.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com