What is Cut-Resistant Tungsten Wire?

- Details

- Category: Tungsten Information

- Published on Monday, 03 March 2025 19:29

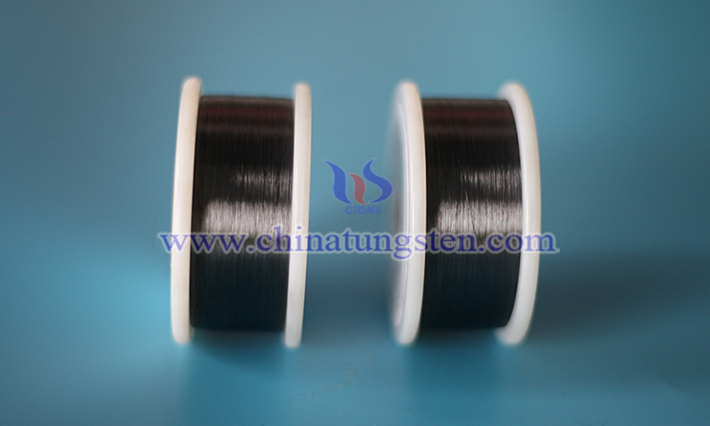

Cut-resistant tungsten wire is a specially treated or modified tungsten-based material. Its core design objective is to enhance resistance to cutting, wear, and high temperatures, making it suitable for scenarios involving high mechanical stress or extreme environments.

I. Basic Definition

Material Basis: It primarily consists of metallic tungsten (W), which inherently has a high melting point (3422°C), high hardness, and high density, but pure tungsten is relatively brittle.

Modification Treatment: Through alloying, coating technology, microstructure optimization (such as grain refinement), or composite material design, its cut resistance is significantly improved.

II. Core Characteristics

Ultra-high Hardness: With tungsten carbide (WC) doping or surface coatings (such as diamond coatings), its hardness can approach that of ceramic materials.

Wear and Cut Resistance: It is resistant to breaking or wearing under repeated friction or cutting stress, with microstructure design (such as fiber orientation) being crucial.

High Temperature Resistance: Tungsten's extremely high melting point makes it suitable for high-temperature environments (e.g., cutting tools, aerospace components).

Corrosion Resistance: Some cut-resistant tungsten wires are enhanced against chemical corrosion through surface passivation or alloying (such as adding nickel or cobalt).

III.Differences from Traditional Tungsten Wire

| Characteristics | Traditional Tungsten Wire | Cut-resistant Tungsten Wire |

| Hardness | High, but prone to brittle fracture | Higher, with improved toughness (e.g., through nanocrystalline structure) |

| Application Scenarios | Light bulb filaments, electrode materials | Industrial cutting tools, bulletproof materials, precision machining |

| Process Complexity | Conventional drawing process | Requires doping, coating, or composite processes (higher cost) |

IV. Typical Application Scenarios

Industrial Cutting Tools: Such as electrode wires for wire electrical discharge machining (EDM), requiring high precision and wear resistance.

Protective Materials: Used as reinforcing fibers in cut-resistant gloves, bulletproof vests, and armor to withstand high-speed impacts.

Medical Equipment: Cutting parts for surgical blades or high-precision medical instruments.

Photovoltaic Industry: Applied in the field of photovoltaic polysilicon cutting, with potential for thinning wires to reduce consumables and replace traditional carbon steel busses.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com