Effect of Zrb2 Addition on 93wt% Tungsten Heavy Alloy

- Details

- Category: Tungsten Information

- Published on Monday, 10 October 2022 21:50

Recently, it has been reported that 93wt% heavy tungsten alloys reinforced with highly uniformly dispersed ZrO2 particles have been prepared by powder metallurgy. The effect of the addition of zirconium boride (ZrB2) on 93wt% tungsten heavy alloys was investigated.

Tungsten heavy alloys (WHA) are generally classified according to the composition of the matrix. The proportion of matrix components significantly affects the mechanical properties of tungsten alloys. Nickel and copper are added to tungsten to make tungsten alloys and lower the sintering temperature. These alloys continue to be used, especially in non-magnetic materials. Iron was later replaced by copper, which increased the strength of the tungsten alloy. For example, Y2O3 and rhenium are added to reduce the size of tungsten particles and improve mechanical and wear properties. While iron is rapidly oxidized, manganese is substituted to lower the sintering temperature and improve shear bond formation.

In a recent study, Wang et al. show that compared with pure tungsten, the mechanical properties of W-ZrB2 alloy are significantly improved, and the originally weak interface has been significantly strengthened. In addition, the addition of zirconium boride has also been shown to be effective for molybdenum alloys with inherent brittleness and weak grain boundaries.

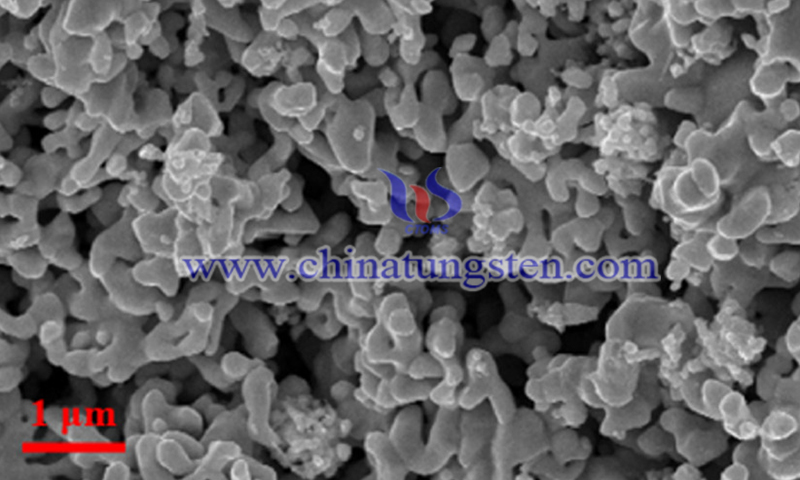

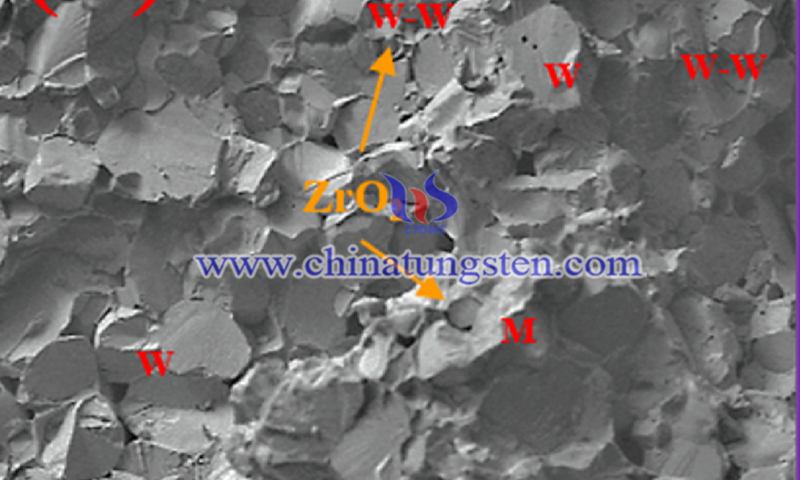

In order to prepare fine-grained tungsten heavy alloy with excellent performance, the ultrafine composite powder 93W-4.9Ni-2.1Fe prepared by two-step reduction method was selected as raw material. Transmission electron microscopy and power spectrum analysis showed that ZrO2 particles were formed by the reaction of ZrB2 with grain boundary oxygen. The maximum tensile strength, elongation and hardness of 93W-0.75ZrB2 alloy can reach 963±16 MPa, 18.4±1.3% and 387.6±4.4 HV, respectively. EBSD characterization revealed that WHA has a two-phase distribution of microstructural features, consisting of BCC W grains without a preferred crystallographic orientation and an FCC γ matrix phase. The W grain size in the 93W-0.75ZrB2 alloy is 19.2 ± 8.6 μm, which is much smaller than that in the 93W alloy.

The results show that a large fraction of W-W interfacial debonding also occurs in the 93W alloy without the addition of ZrB2. Therefore, the 93W alloy exhibits lower strength due to the weakest interfacial bonding. With the increase of the addition amount of ZrB2, the size of W grains decreased significantly, and the number of cleavage fractures of W grains increased, thereby improving the tensile strength. When the addition amount of ZrB2 increased to 0.75 wt%, the ZrO2 particles were uniformly distributed in the alloy and had the effect of oxide dispersion strength.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com