Oxidation Protection of Tungsten Alloys in Nuclear Fusion Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2022 11:37

A recent study conducted by the Anhui University of Technology has proposed new measures for the oxidation protection of tungsten alloys in nuclear fusion applications. As a plasma guide material (PFM), tungsten is persistently used in nuclear fusion reactors. However, it has poor oxidation resistance at high temperatures. When a reactor de-cooling accident occurs, tungsten is rapidly oxidized and volatilized due to air entering the vacuum chamber, which may cause a catastrophic nuclear leakage accident.

The study titled “Oxidation protection of tungsten alloys for nuclear fusion applications: A comprehensive review” has been published in the Journal of Alloys and Compounds 884 (2021). The study was carried out by Tao Fu et al. The researchers at Anhui University of Technology point to the development of self-passivating tungsten alloys and surface protection technology as an effective way to solve the issues.

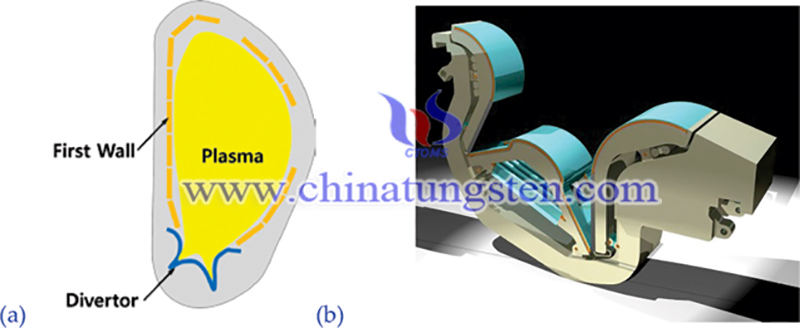

With the development of human society, the energy crisis is becoming more and more serious, and nuclear energy is considered to be one of the most promising energy sources. According to the principle of thermonuclear fusion, a controlled hydrogen fusion reaction to produce fusion energy is considered an ideal way to solve the energy problem in the future. As an important part of the International Thermal Fusion Experimental Reactor (ITER), the reliability and stability of the shunt will remain a key factor for the stable output of nuclear energy.

It needs to withstand damage caused by high heat flow (HHF), high-energy items, electromagnetic radiation, and neutron irradiation from high-energy fusion reactions (14 MeV). Therefore, there are strict requirements for the performance of the PFM. Tungsten metal is considered to be the ideal PFM because of its excellent properties of high melting point, high thermal conductivity, low physical sputtering rate, low fuel retention, and low neutron activation. However, surface melting, cracking, recrystallization embrittlement, and irradiation hardening (embrittlement) of tungsten and its alloys can easily occur in nuclear reactors, leading to severe surface bulging and fracture.

Especially when a loss of coolant accident (LOCA) occurs, in the absence of coolant, the surface temperature will reach over 1000°C in a few days due to decay and heat release of the elements after neutron irradiation. After air and steam enter the vacuum chamber through the fissure, the tungsten armor will undergo catastrophic oxidation.

The tungsten armor is oxidized to volatile and highly radioactive WO3 in a short time. finally, it will be completely lost in 1-2 months, which will cause incalculable catastrophic effects. In order to reduce the loss of W and prolong its service life under a high-temperature oxidation environment. The development of self-passivating tungsten alloys and their surface protection technology has attracted much attention.

This work gives self-passivating tungsten alloys and surface coating protection techniques. Optimization of the preparation process of the alloy (heat treatment of HIPed alloy, etc.) can effectively reduce or eliminate its internal cracks and holes, thermal and residual stresses, and thus reduce its surface roughness and porosity. In addition, some beneficial elements (Ti, Zr, Y, Nb, etc.) can be added to improve the high-temperature strength of W-based alloys, slow down the diffusion of Cr cations, and promote the formation of oxide films.

The two-step deposition process of alloying and surface coating can make the various elements complement each other in the diffusion process so that the coating structure can be further optimized.

Therefore, alloying combined with surface coating technology is a very promising protection method for the applications. It can not only improve the mechanical properties and medium-temperature oxidation protection of tungsten alloys but also effectively improve the high-temperature oxidation resistance of the alloys. Through the diffusion of alloying elements and coatings, the coating structure and composition can be optimized, and the defects caused by the CTE mismatch between the coating and the substrate can also be reduced, effectively improving the oxidation resistance of W-based materials.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com