What is Molybdenum Steel?

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 March 2022 20:03

Molybdenum steel is a high-strength alloy that is used in a variety of industries. Steel alloys made from molybdenum are not only stronger and harder, but they are also highly resistant to heat and corrosion. Electronics, heavy machinery parts, tools, and aircraft parts are often manufactured using steel alloys containing molybdenum.

Molybdenum's unique properties make it useful in steel alloys. Molybdenum is highly heat resistant and can withstand extremely high temperatures, melting at particularly high temperatures, and it is also a good conductor of heat. Molybdenum alone is widely distributed in the United States and seemingly abundant. Many deposits are not now of commercial interest, owing to location and a relatively small amount of ore available, but other deposits are being developed and a stable source of supply seems well assured.

Molybdenum steel alloys retain their strength when exposed to heat and are less likely to expand, soften or deform. Tools and parts that are exposed to extreme friction are often made from these alloys.

Steel made from molybdenum has other advantages. Molybdenum steel is highly resistant to corrosion and is used in stainless steel alloys for greater protection. This alloy is also easy to weld, making it particularly versatile. It is only slightly denser than iron and much lighter than tungsten, which means that molybdenum can provide strength without much change in weight.

Most molybdenum alloys range from 0.25% to 8% molybdenum, and many nickel- and titanium-based steel alloys also include molybdenum. Until the 20th century, tungsten was most often used to make steel alloys. in the late 19th century, researchers began experimenting with the lighter element molybdenum, with excellent results. A French company called Schneider & Co. became the world's first molybdenum steel manufacturer when it used molybdenum alloys to produce armor plating in 1891.

Throughout the first half of the 20th century, molybdenum began to replace tungsten. During World War I, demand for tungsten pushed up prices and made the alternative alloy more attractive. Not only was molybdenum cheaper, but it was also lighter and more heat resistant, making the metal more versatile, and manufacturers continued to find new applications.

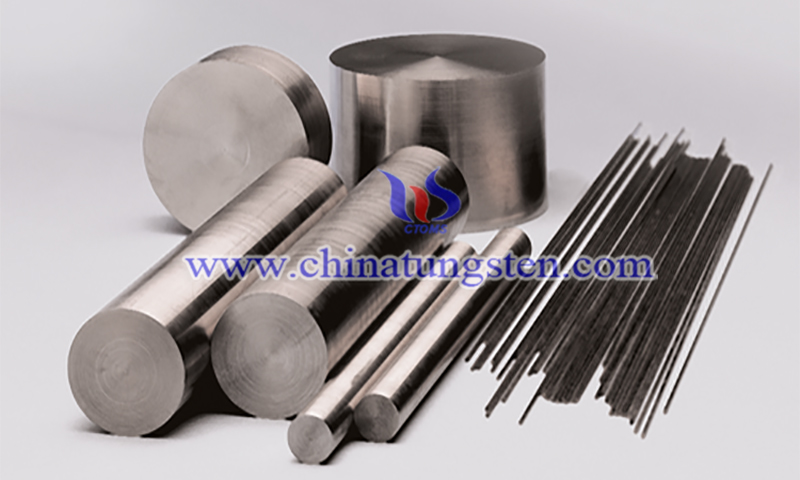

The modern industry continues to take advantage of the properties of this alloy. Molybdenum steel is used to make huge structural beams for the construction industry and tiny filaments for electronic equipment. Components for furnaces and turbines, automotive parts, aircraft components, and heavy machinery parts such as bearings and molds are made from these alloys. Stainless steels containing molybdenum are used throughout the pharmaceutical, health care, food manufacturing, restaurant, and catering industries, and anywhere else where sanitation is an issue and sterile surfaces are required.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com