Nanosized Tungsten Carbide Prepared by Plasma Process

- Details

- Category: Tungsten Information

- Published on Thursday, 21 October 2021 00:21

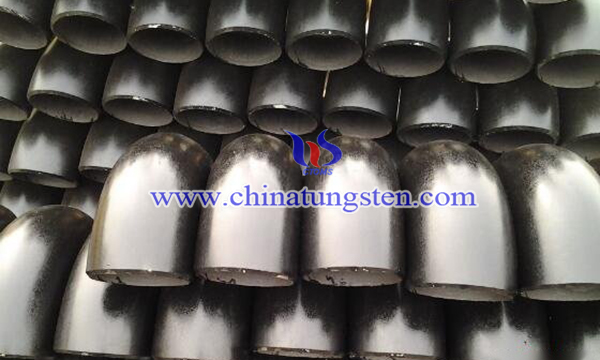

Cemented carbide or tungsten carbide (W2C) is widely used in cutting tools, drilling tools and wear-resistant tools due to its excellent tensile strength, fracture toughness, thermal shock resistance and hardness. By reducing the grain size of WC or adding appropriate reinforcing materials, the mechanical properties of cemented carbide can be greatly improved. The grain size of WC can be suppressed by adding a grain inhibitor or using low-temperature rapid sintering.

Moreover, getting a dense structure with a fine grain size requires low temperature and time consumption. Users claim that the smaller grain size of tungsten carbide significantly improves the mechanical properties of compacted compacts. Therefore, the production of nano tungsten carbide powder is very important.It is reported that a plasma process to produce nanosized tungsten carbide by plasma process using ammonium paratungstate (APT). The production process is as follows:

Argon (99.9%) and hydrogen are used as the primary and secondary plasma gas, respectively. Argon is also used as a carrier gas and an inert gas through the powder feeder to keep the atmosphere in the container inert. Before adding the precursor, the reactor is heated by the generated plasma flame until its temperature reaches a stable level. The mixture of CH4 and H2 also flows through the precursor feed system, bringing the APT powder into the plasma flame. A PTFE-coated polyester filter with a pore size of 1 µm is used to collect the final powder. Before and after each experiment, the reactor was purged with an Ar flow rate of 5 L/min (250 °C, 86.1 kPa total pressure) for 10 minutes.The product is analyzed by using X-ray diffraction (XRD), and the morphology of the particle size is analyzed by using TEM. Measure the total carbon content of the powder with a carbon analyzer). The particle size of the synthetic powder is calculated from the XRD pattern.

In summary, nanosized tungsten carbide has been fabricated through plasma process. The results show that the particle size of the produced tungsten carbide powder is less than 20nm. It is proved that it is feasible to synthesize tungsten carbide nano-powder by plasma using ammonium paratungstate as raw material. Compared with other traditional processes, this is an effective technology for preparing nano-scale tungsten carbide. Due to the high temperature, nano-sized powder can be produced in a shorter time.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com