Synthesis of Spherical Macroporous WO3 Particles

- Details

- Category: Tungsten Information

- Published on Friday, 17 September 2021 01:00

Tungsten trioxide (WO3) has been extensively studied due to its affinity for visible light, chemical inertness, thermal stability, and harmlessness. These excellent properties make this material useful for solar-related applications such as photocatalysts, solar cells, water splitting, and hydrogen generation.

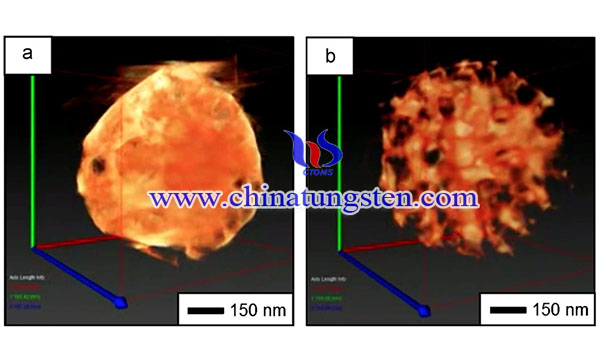

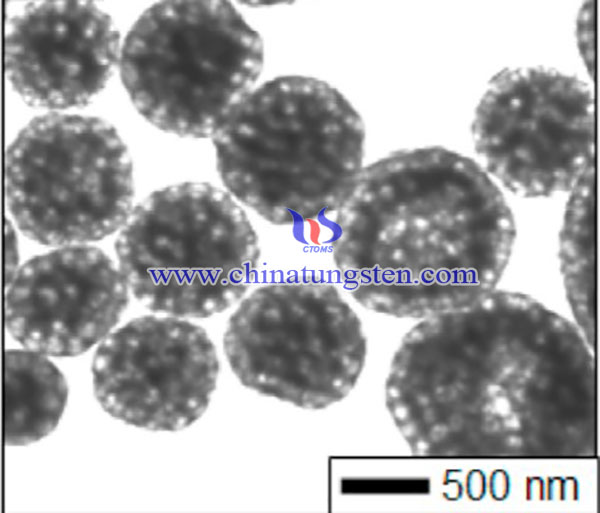

Design of materials with porous structures has been much studied to solve this difficulty. An increase in the porous structural order improves the material performance and reduces the amounts of raw materials used. Thus, the synthesis of spherical macroporous WO3 particles is conducted by a spray-pyrolysis of a precursor suspension containing ammonium tungsten pentahydrate (ATP) as a tungsten source and polystyrene (PS) spheres as a colloidal template. The synthesis process of spherical macroporous WO3 particles is as below:

First, under the condition of no surfactant, PS spheres are synthesized by simple polymerization of styrene monomer. To produce PS spheres with an average diameter of 230 nm, we used 2.00 wt% styrene and 0.04 wt% AIBA, which were processed at a temperature of 75°C. All chemicals were used without further purification. Sonicate the precursor for several minutes at room temperature to ensure that the ATP and PS spheres are well dispersed in the suspension. In order to study the influence of the PS/ATP mass ratio on the porous structure, various mass ratios of PS/ATP from 0.00 to 0.64 were used. In order to study the effect of precursor concentration, we used precursors with a concentration of 10 to 100 g/L.

The sonicated precursor is then placed in an ultrasonic nebulizer (Omron Corp. model NE-U12, operating at a frequency of 1.7 MHz) to produce monodisperse droplets of a few microns in diameter. Then use carrier gas (air; flow rate of 5 L/min) to introduce the generated droplets into the ceramic tube furnace (D=30 mm and L=1.30 m; two fixed temperature zones: 200 and 700 °C). Then use The filter collects the prepared particles.

In summary, synthesis of spherical macroporous WO3 particles were conducted by the spray-pyrolysis method with colloidal templating. The porous particles were generated from a precursor solution containing ATP and PS spheres. The photocatalytic performances of the prepared porous particles were higher than those of non-porous particles.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com