Sensitive Gas Sensor Based on WO3-Au Nanofibers Prepared from Ammonium Metatungstate

- Details

- Category: Tungsten Information

- Published on Sunday, 01 August 2021 18:29

WO3 has extremely high sensitivity for NO2 detection, and has been an ideal material for gas sensor coatings. WO3 has received considerable attention on the potential applications as gas sensors, photocatalyst and electrochromic devices. And it is also reported that doping another kind of oxides into WO3 leads to the formation of semiconductor heterojunction, thus can effectively improve the gas sensitivity of the coatings.

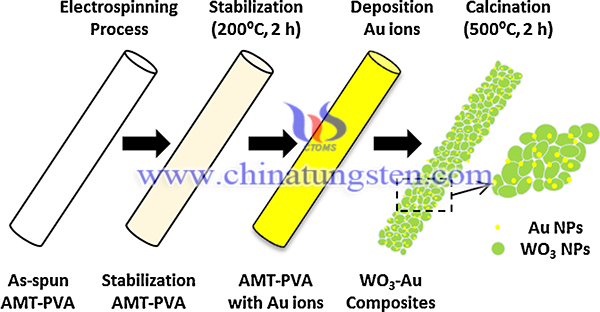

Reducing the size of sensing material is a conventional route to enhance the sensing sensibility. the This is mainly due to a large surface to volume ratio achieved in this case leading to more available surface reaction sites for the absorption of gas species. In order to enhance the sensing performance, sensitive gas sensor based on WO3-Au nanofibers has been prepared from ammonium metatungstate, which reaches a high sensing response of 515.2 at an n-butanol concentration of 500 ppm. The synthesis process of WO3-Au nanofibers is as below:

An electrospinning method was used to synthesize WO3 NFs. In a typical procedure, 10 g of polyvinyl alcohol (PVA, [C2H4O]n, Mw ∼ 72,000 g mol−1, ≥99%) were dissolved in 90 g of H2O, and stirred at 80 °C for 12 h to get PVA/H2O homogenous solutions. Then 1g of ammonium metatungstate (AMT, ≥99.9%) was mixed with 10 ml of the previous solution, to get the weight ratio of PVA:AMT 1:1. To ensure good mixture homogeneity, the resulting solution was then stirred at room temperature for 6 h.

A typical electrospinning setup is composed of a collector, a plastic syringe, with a 21 ga stainless steel needle, and a high-voltage power supply (HV supply from Iseg Co., T1CP 300 304 p, 0–30 kV). The prepared electrospinning solution was loaded into the syringe. The working distance was 10 cm from the needle tip to the collector. The feeding rate was 0.2 ml h−1 and was controlled by a syringe pump (KDS-100). Under these working conditions, an electric field of 1 kV cm−1 led to a stable jet. The as spun AMT-PVA composite NFs were collected on aluminum film, and then collected NFs were annealed at 500 °C for 2 h in ambient air with the heating rate of 3 °C min−1 and cooled in furnace to obtain pure WO3 NFs.

The WO3–Au composite NFs were achieved using a facile method by electrospinning combining a two-step annealing treatment including the gold salt reduction. First, the as spun AMT-PVA composite NFs were stabilized at 200 °C for 2 h in ambient air. Second, the stabilized composite NFs were impregnated with gold solution either by depositing a volume of solution or dipping the sample within the solution. The latter concentration is adjusted to 0.1 M. The exact volume remaining in the sample was not determined but the exact content of gold generated and deposited on WO3 NFs was measured by inductively coupled plasma optical emission spectrometry (ICP). Finally, a calcination step at 500 °C for 2 h is performed, not only to remove the polymer part, but also to reduce the gold salt and obtain Au NPs.

In summary, Sensitive gas sensor based on WO3-Au nanofibers has been prepared from ammonium metatungstate, which reaches a high sensing response of 515.2 at an n-butanol concentration of 500 ppm. The sensing response reaches as high as 515.2 at an n-butanol concentration of 500 ppm, which is ∼60 times higher compared to the response of pure WO3 sensor (S = 8.5).

- AMT Manufacturer & Supplier, Chinatungsten Online: ammonium-metatungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com