Ammonia (NH3) is a colorless and toxic gas, which has a pungent odor. which has a pungent odor. This compound has been widely used in agriculture, fertilizer, factories, food processing, power plants, refrigeration systems, medical treatments, and living environments. Inhalation of ammonia may cause various acute respiratory diseases. It is proved that exposure to ammonia above 50 ppm can irritate the eyes, nose, throat and skin, and extended exposure to ammonia above 200 ppm may even cause chemical burns of skin and permanent lung damage. Thus, the development of ammonia sensors is very significant in the applications of environmental monitoring, industrial process control, and food industry and medical diagnostics. The sensing materials of resistant-type ammonia sensors mainly include semiconducting metal oxides, carbon nanomaterials and conducting polymers.

Tungsten trioxide (WO3) is a transmission metal oxide that has gained much interest due to its relatively wide bandgap of 2.6 ˜ 2.7 eV and high diffusion oxygen vacancy coefficient and its thermal and chemical stability. WO3 has been widely utilized in the field of field-emission devices, photovoltaic devices, photocatalysis, and electrochromic devices.

Recently, catalytic platinum (Pt) nanoparticles (NPs) were doped with WO3 thin films to synthesize Pt/WO3 gas-sensing material as an ammonia sensor. The synthesized composite possesses a sensing response (SR) of 3.73 at a low ammonia concentration of 1 ppm NH3/air at 250 °C. The fabrication process of Pt/WO3 gas-sensing material is as below:

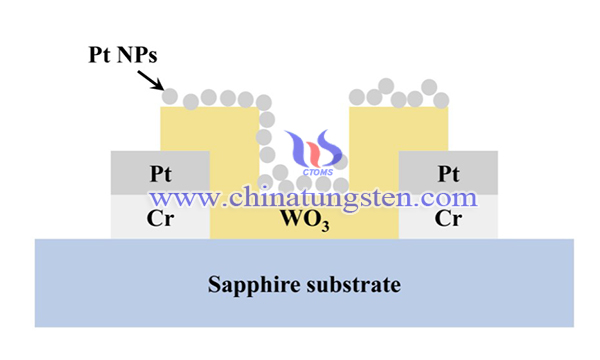

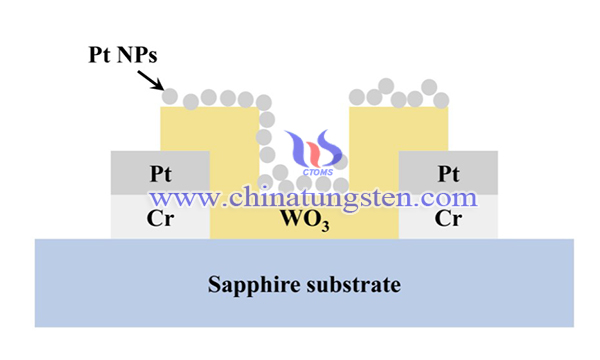

First, wash the sapphire substrate with acetone, hydrochloric acid, and deionized (DI) water to remove undesired particles and organic contaminants. Then, photoresist (PR) coating, photolithography, thermal vacuum evaporation, and lift-off techniques were implemented to deposit 10/15 nm-thick chromium Cr/Pt interdigitated electrodes on the sapphire substrate. The interdigitated electrodes contained eight pairs of metal finger and 2 bonding pads. The length, width, and spacing of these fingers were 1300 μm, 25 μm, and 25 μm, respectively. After that, the PR coating and photolithography were repeated, and an RF sputtering approach was employed to deposit 25 nm-thick WO3 thin films on the Cr/Pt electrodes. The sputtering was conducted using an RF power of 125 W at a working pressure of 3 mtorr in a 30 sccm Ar/O2 (7/3) ambience. After the RF-sputtering and lift-off process, the sample was annealed in N2 ambience using a rapid thermal annealing (RTA) approach at 400 °C for 1 h to achieve the desired pattern.

Firstly, wash the as-prepared WO3 with acetone and DI water. Then, 0.207 g H2PtCl6·(H2O)6 was dispersed into 40 ml of distilled water under stirring at 50 °C for 10 min to obtain a light yellow solution. 0.5 μl of this solution was further dropped on the WO3 sensing layer. In order to perform the reduction of PtCl62−, the as-prepared sample was illuminated under a UV lamp (16 W, wavelength = 254 nm) for 1.5 h. Finally, the device was annealed again in N2 ambience using the RTA at 400 °C for 1 h to stabilize the Pt NPs and enhance the contact property between the Pt NPs and WO3 thin film.

In summary, Pt/WO3 gas-sensing material has been prepared as an ammonia sensor, and the as-prepared product reveals a fascinating sensing response to ammonia. The result demonstrates that an Excellent ammonia sensing response of 26.9 is obtained under 1000 ppm NH3/air gas at 250 °C under 1000 ppm NH3/air gas. Moreover, A lower detection limit of 1 ppm NH3/air is detected. The sensor also reveals a high selectivity towards ammonia gas, and the working temperature is investigated to be as low as 250 °C.

sales@chinatungsten.com

sales@chinatungsten.com