HKUST-1/WO3 Composite for Electrochromic Application

- Details

- Category: Tungsten Information

- Published on Thursday, 29 July 2021 13:26

Electrochromic (EC) materials can change their optical transmittance reversibly by applying an external voltage. In the past decades, scientists have developed various EC materials, including inorganic transition metal oxides (TMO), metal complexes, polymers, and small organic molecules. They have gained a lot interest and have been investigated for its widely applications, such as smart windows, information display, solar heat shutter, and functional energy storage devices.

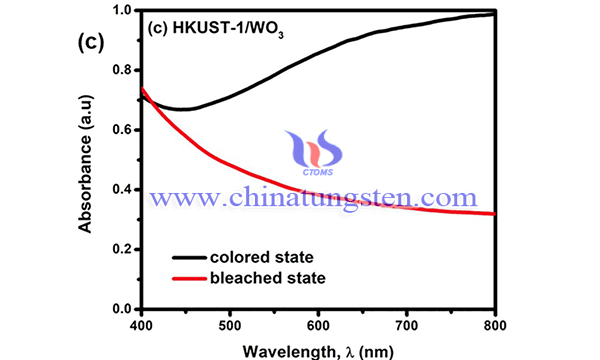

Tungsten trioxide (WO3) is a well-known TMO, and it is a feasible EC material due to its sizeable optical contrast ratio, high coloration efficiency, good stability and low cost. WO3 exhibits visual changes from yellow/colorless to blue due to W (IV) reduction reaction to W (V). Metal-organic frameworks (MOFs) are a group of emerging materials defined as hybrid materials consisting of metal ions or metal ion clusters bridged by organic ligands. HKUST-1 is a copper-based MOF made up of metal units (Cu) and organic ligand.

In order to enhance the physical properties, WO3 and HKUST-1 have been coupled to synthesize HKUST-1/WO3 composite was prepared as a promising EC electrode. The synthesis process of is following steps:

Firstly, wash the ITO glasses with ethanol, acetone, and deionized water (DI) for 15 min. Secondly, 1.76 g (Cu(NO3)2·3H2O) was dissolved in 24 mL DI water while 0.84 g trimesic acid was dissolved in 24 mL ethanol, separately. Both solutions were mixed, and the resultant solution was stirred for one h. The mixture (light blue solution) was then autoclaved and heated at 120 °C for 16 h. The obtained product was washed with ethanol several times and dried at 80 °C for two h. Three w/v% HKUST-1 was then spin-coated onto the conductive ITO substrate (0.75 µL solution; 0.75 cm2 substrate) at 3,000 rpm for 60 s, and the electrode was dried at 200 °C for 20 min.

Firstly, the pH of 0.2 M Na2WO4·2H2O solution was adjusted to 1 using 3 M HCl. An aqueous 0.1 M C2H2O4 (7.5 mL) was poured into the 0.2 M Na2WO4·2H2O (25 mL), and the mixture was continuously stirred (~30 min) until a pale yellow or colorless color was achieved. The mixture was then transferred in a Teflon-lined stainless-steel autoclave with the HKUST-1/ITO glasses, where the conducting side of the electrode facing downward. The deposition of WO3 was accomplished at 100 °C for 1 h. The obtained HKUST-1/WO3 was dried for 5 min at 100 °C.

In summary, HKUST-1/WO3 composite has been successfully synthesized for electrochromic application. HKUST-1/WO3 composite has a high coloration efficiency (296.4 cm2/C). The result also showed excellent switching kinetics (tc = 8.3 s, tb = 2.2 s) and great optical contrast (76.6%) at 633 nm. The excellent stability of HKUST-1/WO3 was obtained over 1000 cycles with electrochromic charge retention of 85.9%.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com