Quasi-Spherical Nanosized Tungsten Prepared by APT

- Details

- Category: Tungsten Information

- Published on Sunday, 27 June 2021 21:27

Tungsten has been widely used as structural materials in aerospace, military, and energy industries owing to its brilliant characteristics such as high mechanical strength and melting point, well thermal conductivity, and good resistance to oxidation. Generally, bulk tungsten is fabricated by powder metallurgy process and high density and fine grain size are critical to achieve outstanding mechanical properties such as the hardness of sintered compacts. Due to its high melting point of 3420 °C, the powder metallurgy process usually requires very high sintering temperatures of 2700–2800 °C to get near fully dense tungsten, which always leads to over growth of the grain size and deteriorates the mechanical properties.

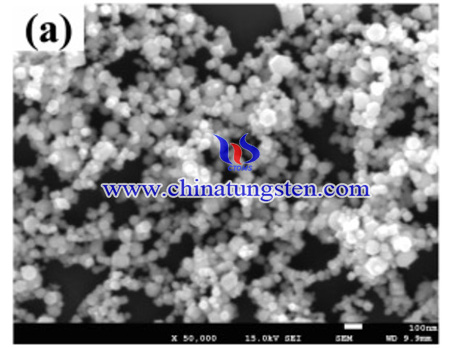

Nanosized tungsten powders can significantly increase the sintering activity of sintered compacts due to its unique nanoscale effect, such as high specific surface and instability of their free surface. In order to overcome these disadvantages, quasi-spherical nanosized tungsten is prepared by using APT as precursor material.

The synthesis of quasi-spherical nanosized tungsten is achieved by RF induction thermal plasma as following steps: Ammonium paratungstate (APT) was used as the precursor and underwent decomposition and reduction reaction in hydrogen RF induction thermal plasma by a one-step way. Such obtained powders were pressed into green compacts under a uniaxial pressure of 250 MPa and holding for 1 min without a binder or any other pretreatment. The green samples were sintered in a tube furnace under flowing hydrogen atmosphere. Different temperatures including 900 °C, 1000 °C, 1100 °C, 1250 °C, 1400 °C and 1500 °C were selected with a constant heating rate of 10 °C/min, and the holding time of each temperature was 2 h.

The structures of synthesized tungsten powder used in this research and sintered compacts were analyzed by X-ray diffractometer (XRD, Philips X'Pert PRO MPD). The morphologies of the powder precursor and sintered samples were examined by transmission electron microscope (TEM, JEM-2100) and field-emission scanning electron microscopy (FESEM, JEOL JSM-7001F).

In conclusion, quasi-spherical nanosized tungsten is prepared by using APT as precursor material. The results show that spherical, well-dispersed nanopowders exhibit high sintering activity and enhance the mechanical properties of sintered specimens. Importantly, 91.3% of TD of sintered compacts is obtained when sintered at 1500 °C for 2 h, and the highest Vickers microhardness value of 606 VHN was achieved. The extremely high hardness value was due to ultrafine grain size and uniform grain distribution of the sintered compacts formed by spherical, well-dispersed precursor nanopowders.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com