Preparation of 12%W/Mt-P Catalyst Using APT for Glycerol Dehydration

- Details

- Category: Tungsten Information

- Published on Monday, 21 June 2021 22:14

The use of biodiesel is being developed to address increasing global concerns regarding the environment and sustainable development. In biodiesel production, a large quantity of glycerol is produced as a by-product. Value-added use of glycerol is important in improving the economic viability of the biodiesel industry. One attractive route is the catalytic dehydration of glycerol to the value-added intermediate acrolein, which is widely used in the synthesis of pharmaceuticals, detergents, and polymers.

WOx-based materials are promising solid acid catalysts for the gas-phase dehydration of glycerol. The 12%W/Mt-P catalyst has been prepared using APT and showed the highest glycerol dehydration conversion of 89.6%.The preparation method of 12%W/Mt-P catalyst is as following steps:

Ca2+-Mt with a cation-exchange capacity of 66 mmol/100 g was obtained from a deposit in Gansu, China. Ammonium paratungstate (APT, analytical grade), H3PO4, CH3COOH, HCl (analytical grade, 36%–48%) and glycerol were purchased from the Hangzhou Shuanglin Chemical Reagent Co., Ltd., China. H2SO4 (analytical grade, 95%–98%) was obtained from the Xilong Chemical Co., Ltd., China. H2C2O42H2O (analytical grade) was obtained from the Shanghai Meixing Chemical Co., Ltd., China. All reagents were used without further purification.

Ca2+-Mt was activated with H2SO4, HCl, H3PO4, or CH3COOH. In all cases, the Ca2+-Mt was first dried at 120 °C for 12 h. The dried Ca2+-Mt (5 g) was added to 20 wt% acid solution (20 mL) in a 100-mL beaker. This mixture was heated at 80 °C for 4 h with constant stirring and then cooled to room temperature. The supernatant was discarded and the solid residue, i.e., acid-activated Mt, was washed with deionized water until the pH reached 5–6 and then dried in an air oven at 120 °C for 12 h. The acid-activated Mt samples were denoted by Mt-S, Mt-Cl, Mt-P, and Mt-Ac, for H2SO4, HCl, H3PO4, and CH3COOH, respectively.

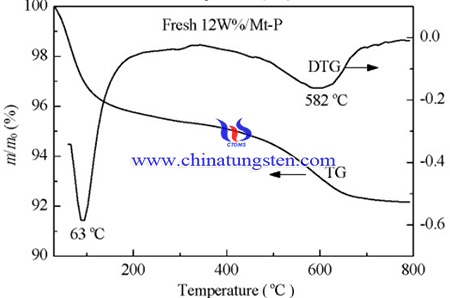

The 12 wt% catalyst was prepared in following steps: APT (0.60 g) and H2C2O42H2O (0.12 g) were dissolved in deionized water (6 mL) at 80 °C. Mt-P (3 g) was added to the solution and the resulting mixture was kept static for 10 h at room temperature. After impregnation, the solid product was dried at 12 °C for 12 h, and calcined in a flow of air at 350 °C for 3 h.

In summary, the 12%W/Mt-P catalyst was prepared using APT as tungsten source and showed the highest catalytic activity. It gave a glycerol conversion of 89.6% and an acrolein selectivity of 81.8% at 320 °C. The W loading affected the type of WOx species on the catalyst surface. The addition of 12% W to Mt-P gave suitable acid sites and appropriate acid strengths for achieving higher catalytic activity and better resistance to deactivation compared with the parent Mt-P and other W/Mt-P catalysts.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com