Ammonium Paratungstate Applied in Niw Based Catalyst for Hydrodesulfurization of DBT

- Details

- Category: Tungsten Information

- Published on Monday, 21 June 2021 12:50

Reducing the sulfur content in hydrocarbon fuels has become an important topic in catalysis due to the continuous stringent environmental legislations. In order to fulfill these requirements, one alternative is to design and develop more efficient catalysts for the hydrodesulfurization (HDS) of crude petroleum. For this reason, the well-arranged mesoporous supports based on silica as MCM-41, HMS, and SBA-15, have attracted considerable attention in the preparation of novel hydrotreating catalysts, due to their outstanding textural properties.

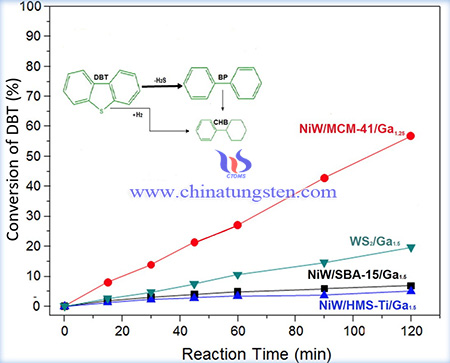

Moreover NiW catalysts is considered to possess better hydrogenation than NiMo and CoMo in the DBT conversion under severe conditions. NiW based catalyst has been supported on silica mesostructured materials as MCM-41 with gallium contents, for the hydrodesulfurization of DBT.

The synthesis method of NiW based catalyst is as following steps: aluminum nitrate nonahydrate [Al(NO3)3·9H2O, ≥ 98%]. Pluronic P123 (EO20-PO70-EO20,Mw = 5800 g·mol− 1), hydrochloric acid (HCl, 37%), tetraethyl orthosilicate (TEOS, Si(OC2H5)4, 99.99%), gallium nitrate hydrate [Ga(NO3)3·8H2O, 99.9%], nickel nitrate hexahydrate [Ni(NO3)3·6H2O, ≥ 98.5%], ammonium paratungstate hydrate (APT,≥ 99%), and hexadecane [CH3(CH2)14CH3, ≥ 99%] were used without further treatment.

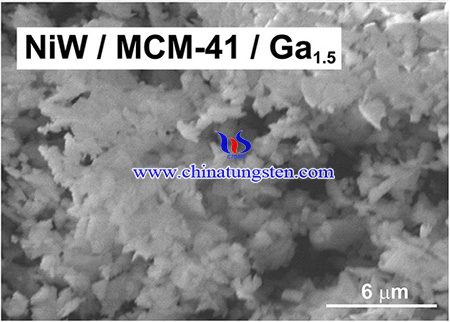

Firstly, the MCM-41 material was synthesized using colloidal silica, a solution of CTAB as surfactant, and aluminum nitrate as the aluminum source. Secondly, a suitable aqueous solution of Ga(NO3)3 was calculated to achieve 1.5 wt.% loadings, then it was mixed with MCM-41 support. The solution was vigorously stirred for 2 h and aged for 12 h under static conditions at room temperature (RT). Finally, the MCM-41 support doped with Ga was dried at 120 °C for 2 h and calcined at 550 °C for 4 h (2 °C/min). The catalyst was synthesized by the pore-filling method using successive impregnations with suitable aqueous solutions of metal salts to achieve 15 wt.% of tungsten and 3 wt.% of nickel. We added first the precursor of W followed by stirring at RT for 2 h, aged for 24 h and dried at 110 °C for 2 h and calcined at 550 °C for 4 h (2 °C/min) after that, when the sample reaches RT conditions, we added the precursor of Ni and followed the same 5 steps. All the samples were stored under argon atmosphere.

In summary, All catalysts were active in HDS of DBT reaction and showed selectivity toward biphenyl as the primary product of the reaction. The NiW/support/Ga1.5 samples performed the highest conversions of DBT, performing a 69%, supported on MCM-41,. The catalyst NiW/MCM-41/Ga1.5 achieved the best performance in the reaction due to the high surface area of MCM-41 favoring a better dispersion of active species as this often improves catalytic activity.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com