Tungsten Copper Application – EDM Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 18 June 2021 09:17

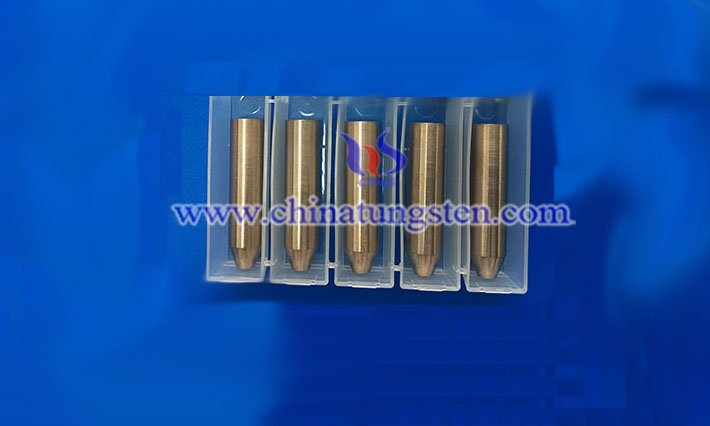

Tungsten copper is widely used as the EDM electrode during the machining. Electric discharge machining refers to a method of machining a workpiece in a certain medium through the electric erosion effect of the pulse discharge between the tool electrode and the workpiece electrode.

Electric discharge machining is a method of processing using electricity and heat that began to be researched in the 1940s and gradually applied to production. In the previous EDM, copper or copper alloy was basically used as the machining electrode.

These two materials are cheap and convenient to use, but the disadvantages are that the copper and copper alloy electrodes are not resistant to electric spark ablation, the electrode consumption is large, and the machining accuracy is also poor, and sometimes they have to be processed multiple times to meet customer requirements. . With the increase in the precision of molds and the increasing demand for many more difficult-to-process materials, EDM technology has become more and more mature, and tungsten copper has gradually become the main consumable for this process, and the amount of use is increasing.

At present, copper-tungsten alloys can be used as electrode materials such as resistance welding electrodes, EDM electrodes, and plasma electrodes. In EDM, its purpose is to transmit processing pulses while at the same time eroding the workpiece with its own minimum consumption. The main reasons for using copper tungsten as electrodes are its fast processing speed, high quality and low loss. At the same time, because the material itself has good electrical and thermal conductivity and good resistance to spark corrosion, this is suitable for high-speed tooling and difficult-to-process materials. The finishing process has obvious advantages. Therefore, the use of CUW electrodes has become more and more extensive.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com