Cr-doped APT for Production of WC-CO Cemented Carbide

- Details

- Category: Tungsten Information

- Published on Thursday, 13 May 2021 05:15

The cemented tungsten carbide hard metals have been widely used in machining, cutting, mining, and drilling tools as well as for wear-resistant equipment. Their wide application stems from their combination of desirable properties, including large hardness, wear-resistance, and fracture toughness values.

WC-based carbides are usually synthesized by sintering the WC-based composites with addition of ductile metal cobalt (binder). The mechanical properties of these materials depend on their composition and microstructure, especially on the grain size of the carbide phase. Thus, well-dispersed Cr-doped APT powder was fabricated for further production of WC-Co cemented carbide with enhanced properties. The synthesis process of Cr-doped APT powder is as below:

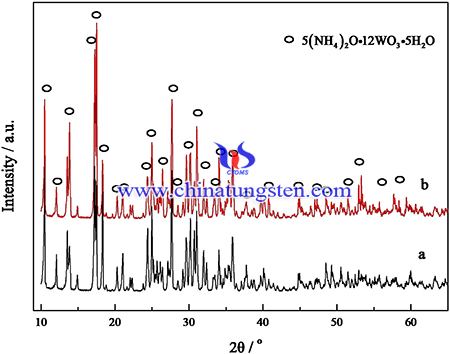

A certain volume of ammonium tungstate solution ([WO3] = 202.8 g/L, [NH4OH] = 96.6 g/L) was added into the reactor, and then a certain amount of (CH3COO)3Cr was added into the solution with Cr concentration of 0.4 wt.% (WO3-0.4Cr) under a temperature of 100 °C and a stirring speed of 50 rpm. After a specified amount of time, Cr-doped APT particles were precipitated from the solution and then filtered and dried. The Cr-doped APT powder was also used to prepare tungsten powder, tungsten carbide powder and WC-Co cemented carbide alloy in subsequent processes.

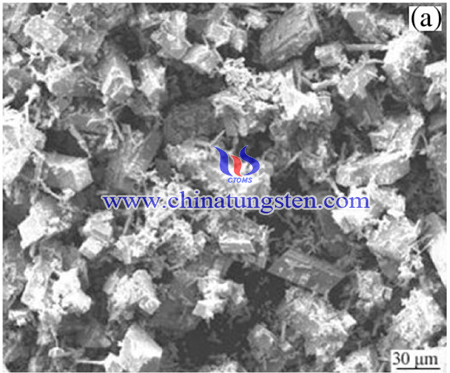

Structural characterization of the Cr-doped APT was performed by Infrared spectrograph. The microstructure of specimens was observed by a scanning electron microscope. XRD examinations were performed with the diffractometer. The average size of specimens was determined with a particle size analyzer.

In conclusion, Well-dispersed Cr-doped APT particles with a fisher particle size of 29 μm were prepared by adding (CH3COO)3Cr into ammonium tungstate solution during the evaporation and crystallization process. In the process, chromium acetate hydrolyzed into amorphous chromium hydroxide. The fisher particle size of the Cr-doped APT powder is around 29 μm, which is much smaller than non-chromium doped APT powder (58.3 μm). The Cr-doped APT powder was then subsequently used to prepare Cr-doped tungsten powder, which particle size was much smaller than that of conventional tungsten powder.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com