NiW HDS Catalysts Produced Using APT Targeting 4,6-DMDBT

- Details

- Category: Tungsten Information

- Published on Thursday, 13 May 2021 04:57

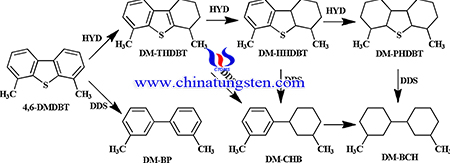

The production of clean fuels with sulfur content less than 10 ppm is of very importance due to the increasingly stringent environmental legislation requirements. The conventional hydrodesulfurization (HDS) catalysts, MoS2 or WS2 clusters supported on γ-alumina (γ-Al2O3) with the promoter of Ni or Co species, were widely used in oil refinery. It was suggested that deep HDS of the highly refractory 4,6-dimethyldibenzothiophene (4,6-DMDBT) required that HDS catalysts have relatively high hydrogenation ability.

MoS2 and WS2 phase doped with the Ni or Co species have been proved to be effective route. Thus, it is promising to fabricate highly-active NiW-based HDS catalyst by utlizing mesoporous zeolite as a support together with tuning the Ni/W ratio. A series of modified NiW HDS catalysts with different Ni/W ratio targeting 4,6-DMDBT were synthesized. Ammonium paratungstate (APT) was applied as tungsten source to produce NiW HDS catalysts with nanosheet morphology. Preparation of NiW HDS catalysts with nanosheet morphology were prepared by hydrothermal method as below:

Ammonium paratungstate (APT) and nickel nitrate (Ni(NO3)2·6H2O) were mixed to prepare aqueous solution. The mesoporous zeolite support was first impregnated with W oxides, and then impregnated with the required amount of Ni species and ethylenediaminetetraacetic acid (EDTA) dissolved in ammonia solution. After each impregnation, the sample was dried under ambient atmosphere for 12 h, and then dried at 100 °C for 12 h. The WO3 loading was 25.8 wt.%, the molar ratio of Ni:W was X:1 (X = 0, 0.15, 0.30, 0.45, 0.55, 0.65, 0.75), and the Ni/EDTA ratio was 1:1. Finally, the dried sample was pelleted (10 MPa), crushed and screened to 40–60 mesh particles. The catalyst with different Ni amount was denoted as NiW/NS-MOR-X (X = 0, 0.15, 0.30, 0.45, 0.55, 0.65 and 0.75), where X stands for the mole ratio Ni/W. For comparison, γ-Al2O3 supported NiW catalyst (NiW/γ-Al2O3-0.55) with Ni/W ratio of 0.55 were also prepared by the same method.

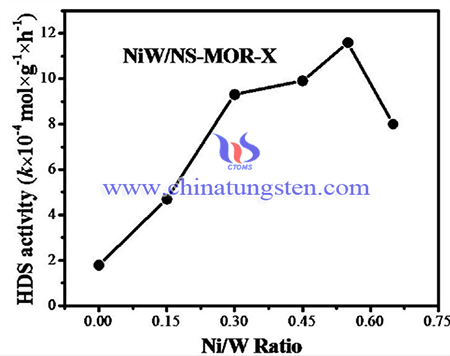

In conclusion, NiW nanosheet catalysts were were prepare with different Ni/W ratio. The obtained catalyst showed a gradually increased activity in the HDS of the 4,6-DMDBT with the rise of Ni content in the prepared catalysts. The highest HDS activity ( 11.1 10-4 mol g-1 h-1)was observed on the NiW/NS-MOR catalyst with the Ni/W ratio of 0.55. the reaction rate constant and TOF on NiW/NS-MOR-0.55 (11.1 × 10−4 mol g−1 h−1 and 3.3 h−1) were much higher than thosethe sulfidation degree of the W oxides comes up to the maximal value for both the NiW/NS-MOR-0.55 (80.7%) and NiW/NS-MOR-0.65 (79.7%) samples The reason for this is due to the fact that the high content of Ni species could benefit the formation of octahedrally polymeric W species, resulting in relatively weak interaction between the W species and the support.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com