Preparation of Tio2/WO3 Using Ammonium Paratungstate for Photocatalytic Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 May 2021 02:04

Titanium dioxide (TiO2) heterogeneous photocatalysis is an advanced oxidation process that degrades a variety of organic compounds, such as synthetic dyes, phenols and chlorophenols, detergents, solvents. Sunlight as a possible source of irradiation makes TiO2 photocatalysis an attractive technology to degrade pollutants in air. However TiO2 only works in conjunction with irradiation of limited wavelength: TiO2 band gap (Eg ≈ 3.2 eV) requires λirr < 385 nm, which rules out 95% of the solar spectrum.

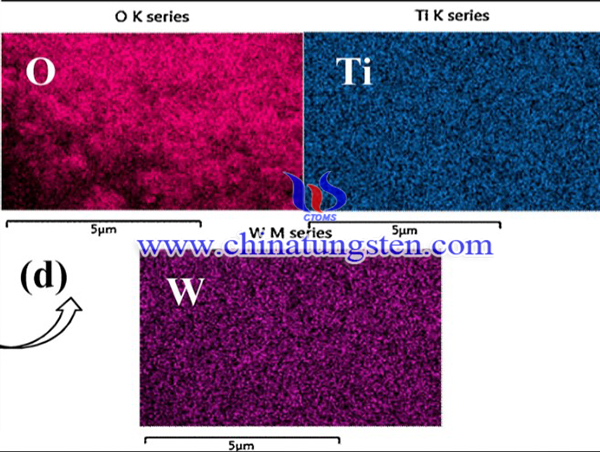

To overcome the shortage of TiO2, Tungsten trioxide (WO3) could be coupled to it. The band gap of WO3 is relatively short (2.6–2.8 eV), thus requiring longer wavelengths for the excitation.TiO2/WO3 was prepared using ammonium paratungstate (APT) for photocatalytic applications. The hybrid catalysts are not only photocatalytically active, but also have photoinduced charge storage ability in the dark.

The synthesis process of TiO2/WO3 composite is as follows:

Titanium butoxide (Ti(oBu)4, ≥ 97.0%), formic acid (≥ 95%), ammonium paratungstate (APT, 99.99%) were used as received.

TiO2 was synthesized by a simple sol–gel method. Titanium butoxide, anhydrous ethyl alcohol, formic acid and water were mixed for one hour at room temperature (molar ratios 60:500:27:1500). Anhydrous ethyl alcohol dissolved titanium butoxide under stirring, followed by the drop-wise addition of water and formic acid. Instantaneous hydrolysis occurs in the reaction mixture yielding a milky sol of hydrated titanium hydroxide.

The molar ratio among ammonium paratungstate (APT), hydrochloric acid (HCl) and water was 0.005:200:500. APT dissolved in HCl under stirring; afterwards the solution was added rapidly to water, resulting in the crash precipitation of a yellow white precipitate of WO3. Most of the water was removed from the precipitate and then washed it several times with deionized water (4 × 100 mL). Finally, we added 20 mL of deionized water to the precipitate under constant stirring to obtain the WO3 suspension.

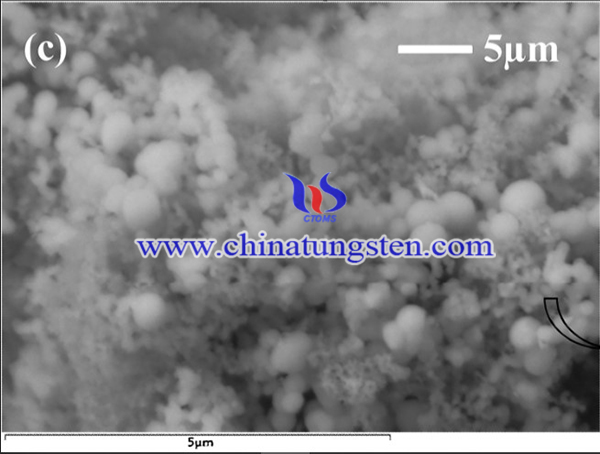

WO3 suspension was added to the stable sol of titanium hydroxide and stirred the hybrid suspension for 3 h before spray drying it. Then the powders were annealed at a temperature of 600 °C in a muffle furnace for 2 h to produce the crystalline TiO2/WO3 composited material.

In summary, TiO2/WO3 photocatalysts was prepared using ammonium paratungstate for photocatalytic applications. The process was facile sol–gel and crash precipitation methods followed by drying. X-ray diffraction confirmed the WO3:TiO2 precursor molar ratio varied at 0.025, 0.05, 0.075 and 0.1, with a surface area of 221 m2/g, 2.88 eV band gap energy. The crystallite size ranges from 15.0 nm to 26.0 nm, and average result is 12.0 nm. The photocatalysts had excellent photocatalytic activity and energy storage ability in the absence of UV irradiation.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com