Hydrothermal Synthesis of Porous WO3 Thin Films Using Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 May 2021 01:48

Photoelectrochemical (PEC) water splitting is believed to be the cleanest, most efficient and sustainable routes to replace the current fossil fuel based energy. H2 produced via PEC water splitting efficiently converted into electricity using fuel cells. Metal oxide semiconductors are known to be suitable materials for PEC water splitting as they are inexpensive and very stable in aqueous solutions.

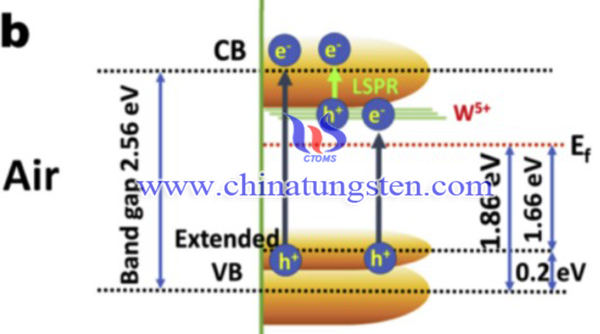

Tungsten trioxide (WO3) is considered as a promising photoanode material for PEC water splitting because it is an inherently good electron transporter (∼12 cm2 V−1 s−1), Unfortunately, the PEC activity of WO3 is limited due to its band gap.

Thus, a hydrothermal synthesis of porous WO3 thin films was conducted using ammonium paratungstate (APT) as raw material. The product showed a higher photocurrent (3.33 mA cm−2 at 2 V vs. RHE). And high levels of oxygen vacancies are introduced via annealing in air for PEC application.

The fabrication procedures of porous WO3 thin films annealing in air was as following:

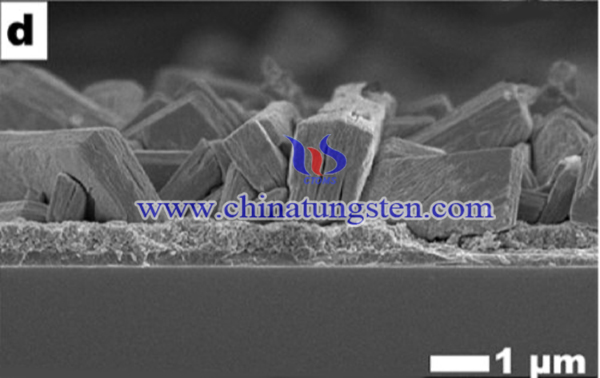

Firstly, 1.0 g ammonium paratungstate (APT) was added to 94 mL de-ionized water and stirred to promote full dissolution. Two milliliters of concentrated H2SO4 was added to the above solution and stirred for 1 h. To this, 4 mL of H2O2 was added and stirred for 1 h to form a clear peroxotungstic acid solution. This solution was then transferred to a Teflon-lined autoclave, filling it to 70%. A previously cleaned FTO substrate was placed inside the autoclave at an angle against the wall of the Teflon-liner with its conducting side facing down. Hydrothermal synthesis was then carried out at 150 °C for 4 h. After the synthesis, the autoclave was cooled to room temperature (299 K), and the resultant WO3-coated FTO was removed and washed with de-ionized water. The hydrothermally synthesized hydrated WO3 thin films were then converted to crystalline un-hydrated WO3 by annealing in air at 500 °C for 2 h (at a ramping rate of 3 °C/min) to form crystalline WO3.

In conclusion, porous WO3 thin films were obtained using ammonium paratungstate as raw material by a facile hydrothermal synthesis route. The air annealed WO3 exhibited a significantly higher photocurrent (3.33 mA cm−2 at 2 V vs. RHE). The air annealed sample shows a maximum IPCE value of up to 2% in the wavelength range of 800–900 nm and ∼3% at nearly 1100 nm. The characterization results show that the annealing atmosphere has a significant influence on the morphology of WO3 without affecting its crystal structure. Annealing in air led to a critical phase transition and reconstructive transformation (dependent on the annealing temperature) to yield a stable monoclinic phase with a significant amount of oxygen vacancies.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com