Preparation Methods of Tungsten Alloy Ball

- Details

- Category: Tungsten Information

- Published on Friday, 02 April 2021 14:40

There are four preparation methods of tungsten alloy balls, namely compression molding, disc pelletizing, squeeze-cut rotation and injection molding.

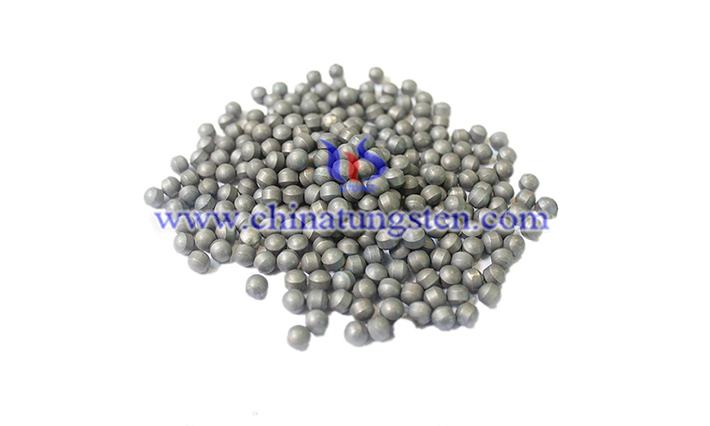

The alloy ball here refers to tungsten heavy alloy ball, tungsten nickel copper ball, or tungsten nickel ferro alloy ball. The balls are with high density, regularly from 17~18.5g/cm3. And the balls are widely used in industry and military area. In industries, they are always used to make into fishing balls as fishing weight with an inner hole for the fishing rope to go through and tight with the fishing lure, or it can be used for hunting industry, which are widely for the civilian industry. In military use, they are applied as weight for guns. Besides the high density, the balls made by WHA is with properties of anti-corrosion, long life time and environmental friendly.

1 Compression molding

The compression molding method is the most mature production process for making tungsten alloy balls, and the process is also relatively simple, which means the volumetric method is used to automatically press and form the powder. The defects are also relatively obvious. Due to the limitation of the mold, there is an annular belt in the middle of the ball blank and the pressing crack is prone to appear at the annular belt. This is related to the resistance of the powder movement to the mold wall. The advantage is that it is easy to realize automatic compression, but the granulation process of the mixture needs to be increased, the mold is worn out, and the efficiency of producing micro-balls is low.

2 Disc pelletizing

This method does not have an endless belt, has high production efficiency and low cost, but the disadvantage is that it needs to be classified, is not suitable for preparing a ball blank of one specification, and the size of the ball blank is difficult to achieve high dimensional accuracy. In the subsequent processing, the amount of grinding is large and the product jumps large, resulting in large processing stress, which affects the crushing performance, and heat treatment is required to eliminate processing stress.

3 Squeeze-cut rotation method

This process is to pre-press the material doped with plasticizer in an extruder, and then cut the extruded round bar into small cylinders, and then rub them into balls by a cone ball machine, or the small cylinder is installed in the disc pelletizing machine and rolled into a ball. The advantage is that the ball diameter is easy to control and the production efficiency is high.

4 Injection molding

Powder injection molding technology is a product of the combination of plastic injection molding technology and traditional powder metallurgy technology. It is known as the most popular powder metallurgy close-to-final shape forming technology in the world today. Its advantage is that it can directly form small metal parts with complex shapes and high dimensional accuracy in large quantities at one time, and the density of each part of the product is uniform, and the performance is excellent. The tungsten alloy ball prepared by the method has high dimensional accuracy and small roundness, and can be processed with little or no processing, and the subsequent heat treatment process is reduced. The disadvantage is that there may be internal defects during the forming process or deformation or cracking during the sintering process, which may not achieve the desired performance.

In addition to the above production process, tungsten alloy ball can also be produced by dry bag isostatic pressing and other preparation methods. However, due to the immature technology, it has not been vigorously promoted and used.

If you have got regular and customized ball requirement, please do not hesitate to contact Chinatungsten for more details, including properties and quotation.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com