Ammonium Paratungstate Applied in Tungsten Oxide Nanorods Electrode For The Detection Of Pesticide

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 February 2021 19:51

Pesticides are crucial part of the farming industry as they can be used to control the insects and weeds for better crop yields. Therefore, the use of pesticides is essential in agricultural and veterinary practices to protect the crops worldwide. However, extensive usage of pesticides would cause toxicity of soils and environmental pollution.

Thus, an electrochemical sensor was fabricated using tungsten oxide nanorod (WO3·0.33H2O) modified with GCE for sensitive detection of fungicide, carbendazim (CBZ). The synthesis process can concludes as follows:

Ammonium paratungstate (APT, 99.99%), HCl 37%, H2O2, 3 wt % in H2O were used as raw materials.

1. Preparation of WO3·0.33H2O nanorods

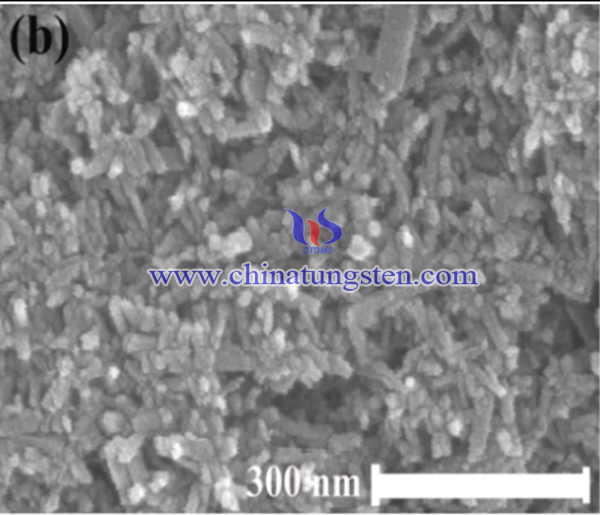

The WO3·0.33H2O nanorods were synthesized using the hydrothermal method (Kanan et al., 2007; Kalanur et al., 2013). Briefly, 0.5 g of ammonium paratungstate (APT) was added to 45 ml de-ionized water and stirred vigorously for 2 h to dissolve it. To this, 2 ml of mixed hydrochloric acid (HCl) was gently added and stirred vigorously for 1 h to produce tungstic acid violet gelatinous solution. The tungstic acid was then dissolved by adding 3 ml of hydrogen peroxide (H2O2) under with the vigorous stirring for another 2 h. The addition of H2O2 dissolved the tungstic acid solution to form the transparent PTA solution. Thus formed PTA solution was delivered to a Teflon container autoclave by filling 70% of its volume and the hydrothermal reaction was carried out in an electric oven at 150 °C for 3 h. For the hydrothermal synthesis, (after 3h) a temperature ramp of 2 °C per min was used. The autoclave was separated from the furnace after completion of the hydrothermal synthesis and cooled to room temperature. After attaining room temperature, the autoclave was opened, and the precipitate of WO3·0.33H2O nanorods were washed with water and centrifuged at 6000 rpm for 30 min. After centrifugation, the precipitate of WO3·0.33H2O was dried overnight in an oven at 60 °C.

2. Fabrication of WO3·0.33H2O modified GCE

A modification factor was affected in the electrochemical reaction of the analyte that played an important role in voltammetry. Initially, the naked GCE surface was washed using double distilled water with the aid of alumina powder using the micro-cloth pads. A suspension of the hydrated tungsten oxide nanoparticles were prepared by dissolving 0.5 mg of WO3·0.33H2O in 10 ml of ethanol via ultrasonic agitation. Using the drop casting method, 1.0 μl of WO3·0.33H2O solution was placed on the GCE surface and dried. The well-coated layer of WO3·0.33H2O was developed onto the surface of the working electrode.

In conclusion, using WO3·0.33H2O modified CPE assembly at the maximized pH value of 4.2. A linear connection was observed between the concentration of carbendazim (CBZ) and the peak current. High sensitivity, good selectivity and lower LOD value (2.21 × 10−8 M) of carbendazim (CBZ) was achieved.WO3·0.33H2O/GCE contains long-lasting stability and reproducibility, which makes them suitable for further analysis. The sensor response of the average recovery values showed 98% for 0.1 mM of carbendazim (CBZ).

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com