Extraction of Pure Ammonium Paratungstate From Tungsten Scraps

- Details

- Category: Tungsten Information

- Published on Saturday, 19 September 2020 11:24

The most accepted recycling of tungsten scraps are hydrometallurgy or hydrothermal treatment methods. The common recycling process of tungsten scraps to produce ammonium paratungstate (APT) is carried out by the oxidation, milling, fusion, dissolution and extraction processes. Among which, oxidation is the key factor to the recovery rate of tungsten scraps.

However, the common oxidation process has a great energy consumption and is time-consuming. The route to solve this is to increase the solubility of solid oxidized products to produce the solution of Na2WO4 by the hydrothermal reflux method. Scientists have invented a extraction of pure ammonium paratungstate from tungsten scraps, from which the energy consumption is less.

The specific preparation process are as follows:

Tungsten scrap in rod shape (20-60 mm) has been prepared. The chemical composition of the tungsten scrap is 5% of cobalt, less than 0.5% of V-Cr-C, and 94.5% of tungsten carbide. The mixing ration of gas was 4-5 to 1. The kiln temperature was increased with increasing the output of oxygen burner. After reaching the temperature of 900◦ for 1hr, which the output of oxygen burner was 5%, average oxygen gas content in the kiln was 28%. When the output of oxygen burner was raised to 12%, the temperature of kiln was about 1010◦ .

During the output of oxygen burner was increased by 12%, the oxygen gas content was increased to 40%. In this study, 100kg of tungsten scraps was set in the kiln. Kiln was rotated for 10s (2 rpm) at intervals of 5min. Scraps was oxidized in the kiln for 30, 60, 100, 120min. Oxidation rate of tungsten scraps was calculated by the residual scraps.

Rotary kiln equipped with oxygen burner Oxidized products of tungsten scraps was set in the hydrothermal reflux device to dissolve and increase the solubility of solid oxidized products of tungsten scraps. 1kg of oxidized products was set in the hydrothermal reflux vessel and heated up at 150◦ and kept for 2hrs. 1mole% of calcium chloride solution was added in the solution of sodium tungsten oxide to precipitate CaWO4. And the hydrochloric acid was added in the CaWO4 to make tungstic acid. Finally an ammonia solution was added in the tungstic acid to make a pure APT. To extract the solid APT, clear solution of APT was boiled and then concentrated.

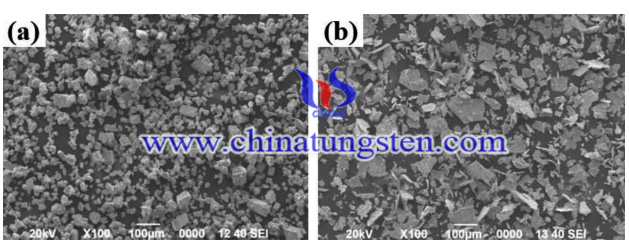

Chemical composition in specific regions of samples determined using an energy dispersive X-ray spectroscopy (EDS) system on the SEM.

In conclusion, using this new extraction of pure ammonium paratungstate from tungsten scraps. High-quality APT with purity of 99.9% can be produced.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com